This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Grande Rilevanza IT-US

Ultrahigh temperature ceramic matrix composites by additive manufacturing using polymer precursors

Principal investigator: Diletta Sciti

Involved personnel: Luca Zoli, Pietro Galizia, Simone Failla

Starting date: 01/01/2016

Duration: 36 months

Total funding: 180.000 €

Action: Ministero degli Affari esteri – Progetti di Grande Rilevanza

Project Coordinator: Diletta Sciti

Partnership: CNR-ISTEC, Italian Aerospace Research Centre, University of Boulder Colorado

The development of a new generation of ceramic materials is a priority for enabling operation under extreme conditions, e.g. temperature of 2000°C or higher, in aerospace and energy applications.

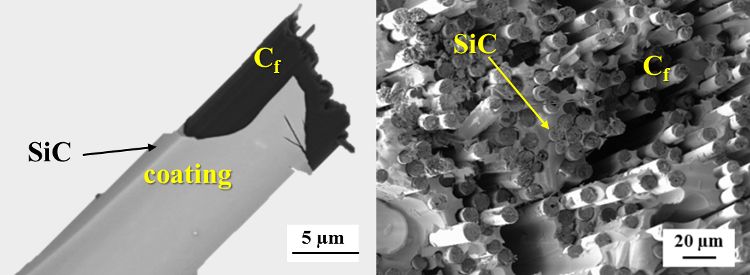

Ceramic Matrix Composites (CMCs) constituted from carbon and silicon carbide are attractive because of excellent mechanical properties but suffer from poor oxidation resistance, limiting their application below 1700°C. Ultra-high temperature ceramics (UHTCs) such as ZrB2, HfB2, HfC, TaC have been identified as potential candidates for operating in harsh conditions owing to their melting point exceeding 3200°C and their resistance to ablation. However, they are severely plagued by poor fracture toughness and thermal shock resistance. UHT- CMCs represent a novel class of materials, which can potentially couple the high oxidation resistance of UHTCs to the damage tolerance of CMCs. Possible final applications include: nozzles for space propulsion, nose caps for reentry vehicles, sharp leading edges, brake systems, heat exchangers and components for stationary gas turbines and jet engines.

Scientific objectives of this project include:

- the enhancement of oxidation and corrosion stability of newly developed nonoxide CMCs and UHT-CMCs by adjusting composition of the matrix. To this purpose, self-healing additives are implemented in the microstructure and ultra-high temperature ceramics UHTC are developed for being used as matrix within the fibrous preforms.

- Development of scientific understanding of the laser flash pyrolysis mechanism enabling deposition – in a few seconds – of nanoscale layers of polymer derived ceramics.

- Evaluation of UHT-CMCs at high temperatures by techniques developed at the laboratory level and in relevant environment.

The project relies on the synergistic expertise and facilities at ISTEC-CNR, CIRA (Italian Aerospace Research Centre) and University of Colorado at Boulder (Prof. Rishi Raj). ISTEC excels in high-level characterization and the measurement of high temperature mechanical and oxidation properties. Colorado has unique expertise in the processing of CMCs from polymer precursors. CIRA has unique facilities for plasma wind tunnel tests. The program will lead to the training of young researchers and enhance the competitiveness of CNR in Europe in strategic fields such as energy, transport and aerospace.

Insights

- http://www.esteri.it/mae/it/politica_estera/cooperscientificatecnologica/programmiesecutivi/progettigranderilevanza

- http://www.esteri.it/mae/resource/doc/2017/08/progetti_grande_rilevanza_finanziati_2016_-_web.pdf

Publications & patents

- P. Galizia, S. Failla, L. Zoli, D. Sciti, Tough salami-inspired Cf/ZrB2 UHTCMCs produced by electrophoretic deposition, J. Eur. Cer. Soc., 38, 403-409 (2018).