This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

GEA

GEopolymer based Adsorbents for effective adsorption and selective separation of CO2 and eutrophication pollutants

Principal investigator: Valentina Medri

Starting date: 16/10/2023

Duration: 24 month

Total Funding: 203.604,00 €

Action: PRIN: PROGETTI DI RICERCA DI RILEVANTE INTERESSE NAZIONALE – Bando 2022

CNR-ISSMC role: Coordinator

Coordinator: Valentina Medri (CNR-ISSMC)

Consortium: Consiglio Nazionale delle Ricerche (CNR-ISSMC); DICAM – Università di Bologna

GEA project deals with the development of synthetic alkali aluminosilicates, namely geopolymers, for separation and purification applications, exploiting adsorption mechanisms for the capture of CO2 or nitrogen or phosphorous-based pollutants in wastewater. The goal includes the identification of when and why a geopolymer-based material can be preferred to a benchmark adsorbent.

It is noteworthy that geopolymers are environmentally friendly (and low cost) materials:

- they are produced at max 80°C with a water-based synthesis from naturally abundant materials such as clays using a green chemistry approach;

- some reagents may be obtained from wastes, still guaranteeing a controlled purity and stoichiometry;

- it is possible to reuse geopolymers after exhaustion in other applications (e.g. in new building materials), that is a crucial advantage over the benchmark adsorbents such as activated carbon.

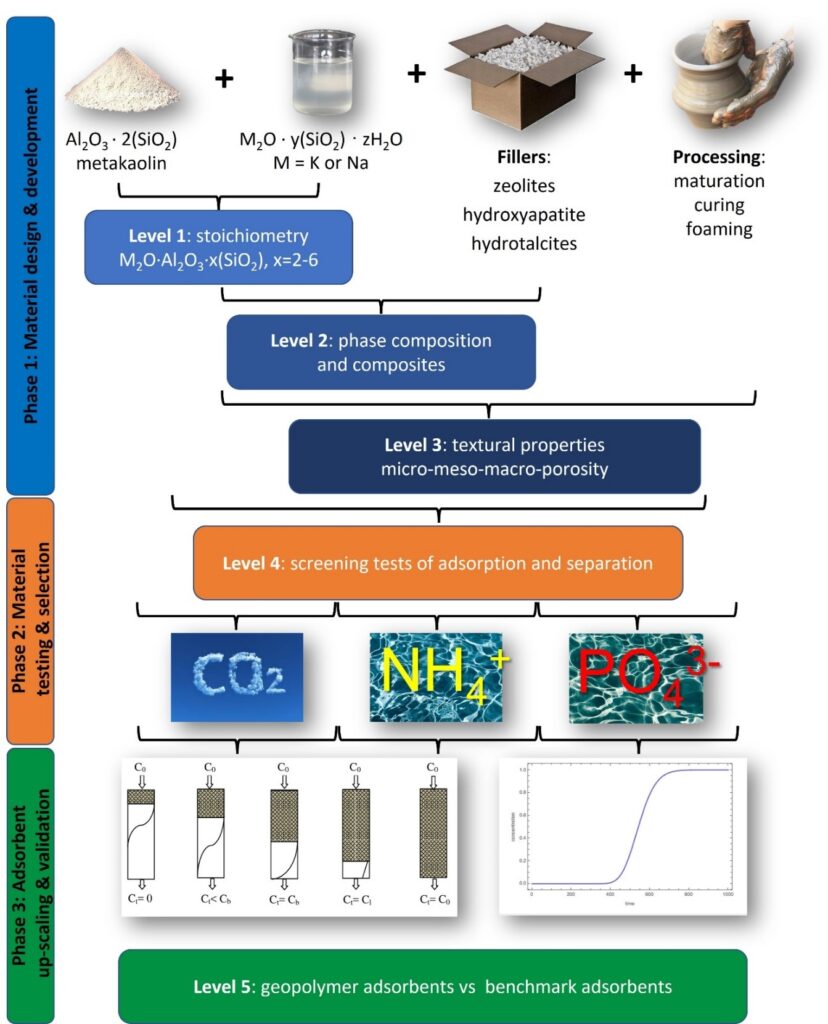

GEA will develop a geopolymers platform with the ambition to link adsorption/desorption ability and selectivity versus ionic species and gases to compositional and morphological variables such as: stoichiometry, phase composition (also in composites) and textural properties (directly linked to micro-macrostructure). Acting on the variables, porosity, pore size/distribution and chemistry will be conveniently tuned for the targeted adsorption applications of the project, that are:

1) carbon dioxide adsorption and separation from CO2 concentrated sources (e.g. flue gases), in the context of a Carbon Capture and Storage (CCS) strategy;

2) removal of ammonium and phosphates from wastewater with the aim of eutrophication prevention and critical raw materials recovery (recovery and separation of phosphorus).

The results of GEA will disclose the possibility to customize eco-friendly materials (low energy production process) for specific adsorption purposes and to identify geopolymer matrices able to actively increase in composites the performances of other adsorbent such as zeolites, apatites, hydrotalcites. Furthermore, the project results will finally clarify the real potentiality of geopolymers-based adsorbents in comparison to benchmark adsorbents at the large scale.

It follows that impacts of GEA in the field of adsorption are expected to be:

- Scientifically sound and relevant, as the project will overcome the main bottlenecks currently hindering a wider use of geopolymer adsorbents, enhancing the reproducibility of the results also related to raw materials and processing, and the gap between research studies, often using unrealistic scenarios (e.g. synthetic wastewaters), and real ones which are much more complex.

- Technologically relevant since the use of geopolymers allows to easily customize the shape of the solid adsorbent to the separation plant and increase long-term mechanical performances and duration.

- Economically relevant because geopolymer synthesis can be performed with a fairly low energy input.

In GEA, previous knowledge will be exploited to generate the platform of a new family of eco-friendly and less expensive solid adsorbents, developing different levels of systematic understanding and modelling of the effect of the main geopolymer variables on adsorption performances. The GEA project will be articulated in 3 Phases (Fig. 1), briefly described below. Phase 1 related to Material Design & Development and Phase 2 related to Material Testing & Selection will be conducted iteratively.