This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

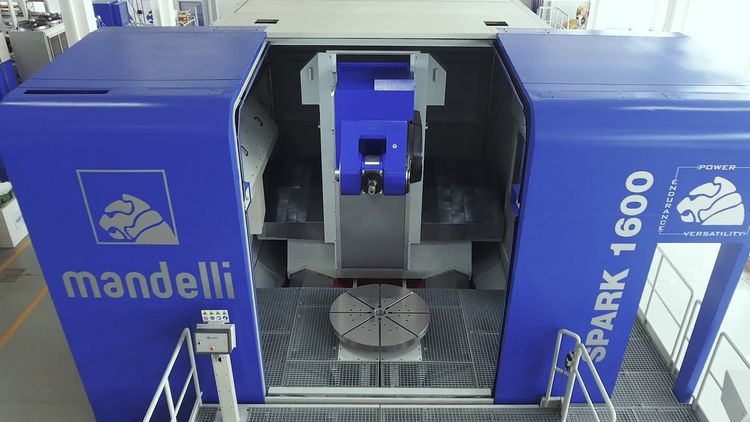

SP@RK-4.0-I.E.S

High-Performance, Hybrid and Smart Production System that Integrates Additive Manufacturing with Milling and Turning of High-Tenacity Materials

Principal Investigator: Mariarosa Raimondo

Involved personnel: Federico Veronesi, Alessandro Corozzi, Guia Guarini

Administrative management & Financial reporting: Laura Mengozzi

Starting date: 01/01/2018

Duration: 36 months

Total funding: 3.499.100,00 €

Action: MiSE – Industria Sostenibile FRI (2017)

Project Coordinator: Massimo Bertuzzi (Mandelli Sistemi S.p.A., Piacenza)

Consortium: Mandelli Sistemi S.p.A., Hypertec Solution S.r.l. (Rovereto, TN), Provide Solution S.r.l. (Piacenza), Consorzio MUSP (Piacenza), Halle Institute for Economic Research IWH (Zurich, Switzerland)

The project aims at developing innovative technology in the field of production systems for the manufacturing of tough materials with high performances, like titanium alloys and nickel-based superalloys.

The main objectives of the project are:

- to increase the productivity and production efficiency for the reduction of manufacturing and machine management costs;

- to develop advanced digital systems for self-diagnostics, connection of the machine in the network, optimization of consummation and operation.

The role of ISTEC will be focused on the realization of amphiphobic surfaces inside the evacuation zone to promote shavings slippage. This solution could solve the problem of shavings adhesion to the machine, enhancing their slippage and hugely reducing the stops for their removal.

To reach such target, it will be necessary to produce a functional surface with high mechanical resistance to impact and abrasion. In fact, the target is to guarantee the durability of the treated surface impacted by the shavings.