RdS

Fuel cells for stationary and cogenerative applications

Enabling technologies for the electric system research: components and materials

Electrochemical systems for energy production and storage

Principal investigators: Elisa Mercadelli, Alessandra Sanson

Involved personnel: Angela Gondolini, Paola Pinasco

Starting date: 2006

Duration: 144 months

Total funding: 1.175.000 €

Call: Economic Development Ministry of Italy (MiSE)-CNR Agreement

Coordinator: Vincenzo Antonucci (CNR-ITAE), Monica Fabrizio (CNR-ICMATE)

Consortium: 3 CNR centres

Officila website: http://www.ricercadisistema.cnr.it/

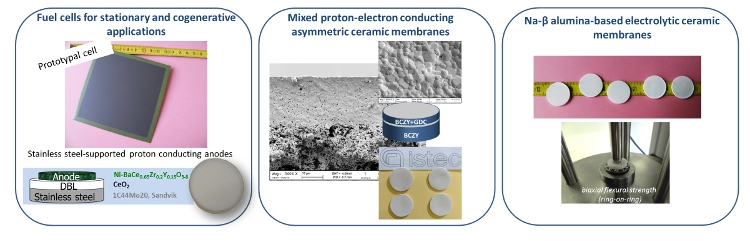

Fuel Cells for stationary and cogenerative applications;

Aim of the project was the evaluation of different FC technologies for cogenerative applications through the simulation, theoretical study, design and systems demonstration as well as the development of new materials, components and prototypes.

In this context, CNR-ISTEC took part of the project activity “Development of materials and components for next generation FC for cogenerative applications”, developing and producing anion conducting Solid Oxide Fuel Cells with prototypal dimension (10 x 10 cm) as well as stainless steel-supported anodes for proton conducting FC.

Enabling technologies for the Electric System Research: components and materials;

Among the different goals of the project, ISTEC was involved in the project activity “Dense ceramic membranes for hydrogen purification”. Dense membrane technologies are able to selectively separate hydrogen with purity values higher than 99%, promoting the production of energetic vectors and fuels from renewable sources.

In this context CNR-ISTEC has developed all-ceramic mixed proton-electron conducting membranes with asymmetric architecture, operating in the 600-800°C temperatures range.

Electrochemical systems for energy production and storage;

The general aim of this project was:

• the optimization of electric storage systems currently available on the market but not yet competitive for ad-hoc applications (i.e. High temperature batteries, Lithium ion batteries, Vanadium Redox Flow Batteries);

• development of new technologies such as metal-air batteries and synthetic methane storage through CO2 and H2O electrolysis.

In this context, CNR-ISTEC was involved in the development and production of electrolytic ceramic Na-β alumina membranes for the production of planar NaNiCl prototypal batteries.

Publications

- E. Mercadelli, A. Gondolini, D. Montaleone, P. Pinasco, S. Escolástico, J.M. Serra, A. Sanson “Production strategies of asymmetric BaCe0.65Zr0.20Y0.15O3-δ–Ce0.8Gd0.2O2-δ membrane for hydrogen separation” Int. J. Hydrogen En., In Press

- D. Montaleone, E. Mercadelli, A. Gondolini, M. Ardit, P. Pinasco, A. Sanson “Role of the sintering atmosphere in the densification and phase composition of asymmetric BCZY-GDC composite membrane” J. Eur. Ceram Soc. 39 (2019) 21–29.

- D. Montaleone, E. Mercadelli, S. Escolàstico, A. Gondolini, J.M. Serra, A. Sanson “All-ceramic asymmetric membranes with superior hydrogen permeation” J. Mater. Chem. A, (2018) 6,15718.

- D. Montaleone, E. Mercadelli, A. Gondolini, P. Pinasco, A. Sanson “On the compatibility of dual phase BaCe0.65Zr0.2Y0.15O3-δ based membrane for hydrogen separation application” Ceram. Intern. 43 (13) (2017) 10151–10157.

- E. Mercadelli, D. Montaleone, A. Gondolini, P. Pinasco, A. Sanson “Tape-cast asymmetric membranes for hydrogen separation” Ceram. Intern. 43 (11) (2017) 8010–8017.

- E. Mercadelli, A. Gondolini, P. Pinasco, A. Sanson “Stainless Steel Porous Substrates Produced by Tape Casting” Metals and Materials International, 23 (2017) 184–192

- E. Mercadelli, A.S. Aricò, A. Gondolini, S. Siracusano, M. Ferraro, V. Antonucci, A. Sanson “Influence of powders thermal activation process on the production of planar β-alumina ceramic membranes” Journal of Alloys and Compounds 696 (2017) 1080-1089

- A. Caldarelli, E. Mercadelli, S. Presto, M. Viviani, A. Sanson “Leaching effect in gadolinia-doped ceria aqueous suspensions for ceramic processes” Journal of Power Sources 326 (2016) 70-77

- A. Lanzini, C. Guerra, P. Leone, M. Santarelli, F. Smeacetto, S. Fiorilli, A. Gondolini, E. Mercadelli, A. Sanson, N.P. Brandon “Influence of the microstructure on the catalytic properties of SOFC anodes under dry reforming of methane” Materials Letters164 (2016) 312–315

- E. Mercadelli, P. Pinasco, A. Gondolini, A. Sanson “Technological Issues in the Manufacturing of Anode-Supported Half-Cells” ECS Transactions, 57[1] (2013) 823-832.

- A. Sanson, E. Mercadelli, A. Gondolini, P. Pinasco “Unconventional Approaches for the Production of Large Area SOFC” ECS Transactions, 57[1] (2013) 717-726.

- E. Mercadelli, A. Gondolini, P. Pinasco, A. Sanson, S. Barison, M. Fabrizio “Key Issues in Processing Metal-Supported Proton Conducting Anodes For SOFC Applications” ECS Transactions, 35 (1) (2011) 1761-1769.

- A.Sanson, P.Pinasco, E.Roncari “Influence of pore formers on slurry composition and microstructure of tape cast supporting anodes for SOFCs” Journal of the European Ceramic Society 28 (2008) 1221–1226.