BALTIC

Project p.n.r.m. “development and engineering of high perfomance balistic protection systems based on TiB2-B4C ceramic composites”

Principal Investigator: Diletta Sciti

Involved personnel: Simone Failla, Pietro Galizia, Claudio Capiani, Cesare Melandri

Starting date: 26/01/2018

Duration: 24 months

Total funding: 587.500 €

Call: Ministero della difesa – Piano Nazionale della Ricerca Militare

Project Coordinator: Diletta Sciti

Consortium: CNR-ISTEC, Bitossi Industries

The purpose of this project is to develop novel non oxide light ceramic materials for individual and vehicular protection systems. The challenge is production of high performance materials at reduced cost. For instance, boron carbide (B4C) is the lightest and hardest ceramic, but also the most expensive material being used today in ballistic protection due to its high sintering temperature (above 2000°C).

On the other hand, titanium diboride (TiB2) is a hard and stiff ceramic, particularly interesting for ballistic protection but not yet widely used due to high production costs and the requirement to sinter it with applied pressure. Beside possessing a very high melting point (>3000°C), TiB2 has a very high hardness (25 GPa) and very high electrical conductivity similar to that of metals. This feature can be conveniently exploited to machine ceramic pieces by electro-discharge machining, a less expensive technique compared to conventional diamond too machining.

In this project, boron carbide and titanium diboride will be combined following the composite approach. Both B4C and TiB2 rich compositions will be studied and fabricated. TiB2 addition to B4C makes the latter electrically conductive, B4C addition to TiB2 may improve the densification, increase the hardness and decrease the weight.

The project duration is 2 years. The first year is dedicated to design, development and microstructural/mechanical characterization of B4C-TiB2 composites. Materials production will be followed by an intense characterization including microstructure analysis and measurements of mechanical properties. In spite of significant scientific investigations, it has not yet been possible to establish an exact relationship between ceramic properties and ballistic performance because they have not yet been studied or because they are classified information. However, it is indisputable that high hardness and high modulus are necessary for ballistic efficiency.

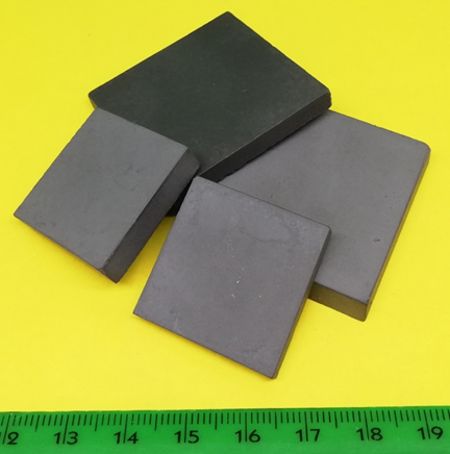

The second year is for fabrication of small ceramic plates by either pressure or pressureless sintering techniques and subsequent ballistic tests. The critical analysis of data obtained from the characterization above will allow us to identify one or more improved materials to be used for the fabrication of larger ceramic plates that will be assembled with suitable backing and further tested.

For ballistic tests, assembling of ceramic piece with its backing and performance evaluation the project will benefit from collaboration with Industrie Bitossi. In the final part of the project, ballistic tests will be conducted at Defence Administration following procedures dictated by STANAG or NIJ standards.

Publications & Patents

- S. Failla, C. Melandri, L. Zoli, G. Zucca, D. Sciti, Journal of the European Ceramic Society Hard and easy sinterable B4C-TiB2 -based composites doped with WC, J. Eur. Ceram. Soc. 38 (2018) 3089–3095. doi:10.1016/j.jeurceramsoc.2018.02.041.