This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Dynamic Mechanical Analyzer

Supervisor : Elisa Mercadelli

Dynamic Mechanical Analysis measures the viscoelastic properties of materials as a function of time, temperature, and frequency.

These analyses allow the determination of:

• mechanical properties, such as moduli, strength, strain at break, damping;

• glass transition temperature, degree of crystallinity, additives/fillers effect, etc.

Output values:

Complex Modulus, Storage Modulus, Loss Modulus, Complex/Dynamic Viscosity, Time, Creep Compliance, Stress/Strain, Frequency, Tan Delta (δ), Static/Dynamic Force, Sample Stiffness, Temperature, Displacement.

Modes of Operation:

• Multi strain or multi stress

• Multi Frequency/Strain or multi frequency/stress

• Creep

• Stress relaxation

• Controlled force

• Iso-strain

• Strain rate

Materials tested at CNR-ISTEC: Ceramic green tapes produced via tape casting; Polymeric scaffolds and hybrid composites for applications in regenerative medicine; Materials for damping applications; UHTC Matrix Composites (UHTCMCs) for aerospace applications.

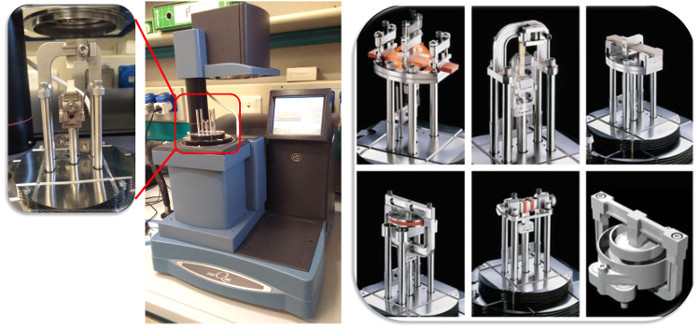

Dynamic Mechanical Analyzer, DMA Q800, TA Instrument

• Maximum/ minimum Force: 18 N / 0.0001 N.

• Force Resolution: 0.00001 N.

• Strain Resolution: 1 nm.

• Frequency Range: 0.01 to 200 Hz.

• Dynamic Sample Deformation Range: 0.5 µm to 10 mm.

• Temperature Range: 25 to 600°.C

• Heating Rate: 0.1 to 20°C/min.

• Data sampling interval: da 0.1 a 1000 s/pt.

• Clamps available at CNR-ISTEC: Single/dual cantilever, Tension film/fibre, Compression, Submersion compression.