Universal mechanical loading frame

Supervisor: Cesare Melandri

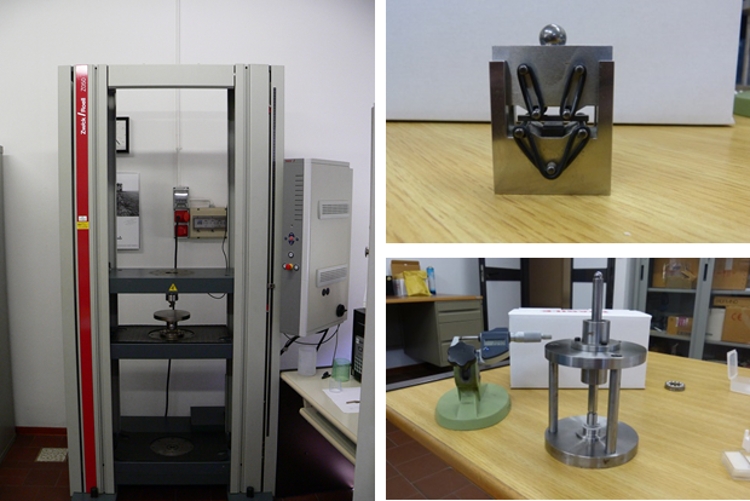

Zwick-Roell Z050

Universal screw-driven load frame for mechanical testing at room temperature. Possibility to carry out tests up to 50 kN with cross-head speed from 0.0005 to 400 mm/min. This machine is mainly used for compressive and flexural tests in 3 and 4 point configuration of various types of ceramic and other materials and it allows also to perform tensile tests.

It is equipped with various fully-articulated steel fixtures that can allocate specimens with a broad range of size and shape.

It comprises a flexible software that allows to perform conventional loading tests, but also to customize dedicated programs, i.e. loading/unloading cycles.

Main technical features:

- Loading frame: 50 kN.

- Cross-head speed: 0.0005 – 400 mm/min.

- Flexible test programming.

- Digital machine.

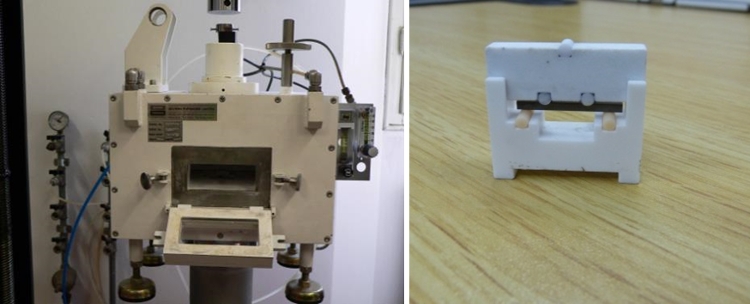

Instron mod. 1195

Universal screw-driven load frame for mechanical testing at room and high temperature. Possibility to carry out tests up to 100 kN with cross-head speed from 0.05 to 500 mm/min. This machine is mainly used for compressive and flexural tests in 3 and 4 point configuration of various types of ceramic and other materials. Tensile tests are also possible.

It is equipped with semi-articulated allumina fixture that can allocate specimens with maximum length of 30 mm.

Maximum operating temperature: 1500°C in controlled environment.

It comprises a flexible software that allows to perform conventional loading tests, but also to customize dedicated programs, i.e. loading/unloading cycles.

Main technical features:

- Loading frame: 100 kN.

- Cross-head speed: 0.05 to 500 mm/min.

- Load cells: 500 kg and 10000 kg.

- Furnace up to 1500°C in controlled environment.

Instron mod. 6025

Universal screw-driven load frame for mechanical testing at high temperature. Possibility to carry out tests up to 100 kN with cross-head speed from 0.005 to 1000 mm/min. This machine is mainly used for compressive and flexural tests in 3 and 4 point configuration of various types of ceramic and other materials.

It is equipped with two semi-articulated silicon carbide fixtures that can allocate specimens with length from 25 to 60 mm.

Maximum operating temperature: 1500°C in air.

It comprises a flexible software that allows to perform conventional loading tests, but also to customize dedicated programs, i.e. loading/unloading cycles.

Main technical features:

- Loading frame: 100 kN.

- Cross-head speed:0.005 – 1000 mm/min.

- Load cell: 10 kN.

- Furnace up to 1500°C in air.