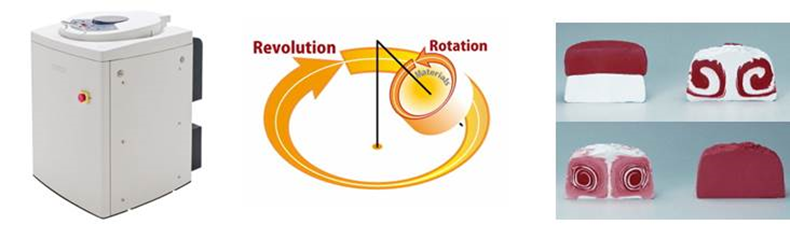

Planetary Centrifugal Mixer

Supervisor: Elettra Papa

The planetary Centrifugal Mixer is a mixer and a deaerator that disperses materials uniformly and deaerates at the same time. The mixer is a no-blade mixer that mixes materials employing “rotation” and “revolution”.

The mixer uses a mechanism where the container holding the material revolves clockwise and the container itself rotates counter-clockwise. The centrifugal force (400G) produced by the high-speed rotation and revolution depresses the material in the container, and generates vertical spiral convection. This vertical spiral convection is continuously generated to blend and disperse the materials, obtaining in few minutes homogeneous compounds with perfectly dispersed solids, without air residues and directly in the container.

Benefits:

- utilized in processing of various materials such as geopolymers , adhesives, silicon resins and epoxy resins, nanotube, sealing material for LEDs, ointment preparation at dispensing pharmacies, etc..

- mixing of high-viscosity materials, difficult to mix with propeller mixers or stirrers, in a small amount of time

- dispersing without shearing

- high reproducibility of dispersion

- no need to clean the apparatus. The mixing action takes place directly within the sample, maximizing the recovery of the product at the end of the process

- reduced process times allow to obtain remarkable amounts of mixtures just-in-time, which is fundamental for products that require an immediate application after mixing.

Planetary Centrifugal Thinky Mixer ARE-500CE, Thinky Corporation

- Mixing mode: revolution speed from 400 to 1000 rpm, variable; rotation speed 980 rpm

- De-foaming mode: revolution speed from 400 to 2000 rpm, variable; rotation speed 63 rpm

- Max mixing volume: 500 ml / 1100 g

- Optional integrated adapters with different capacity and geometry and cooling adapter

- Max viscosity of samples: no limits. It works with liquids, creams, paste, powders, etc.