Spin Coater

Supervisor: Alex Sangiorgi

Spin-coating is a technique based on the centrifugal force that allows uniform thin film deposition on planar substrates. The device that allows performing such deposition is called a spin coater. A solution of the material of interest is placed in the middle of the substrate, which then starts spinning at high speed. Rotation continues until the excess solution is ejected from the surface and the desired coating thickness is achieved. The two main factors dictating the film thickness are rotational speed and solution viscosity.

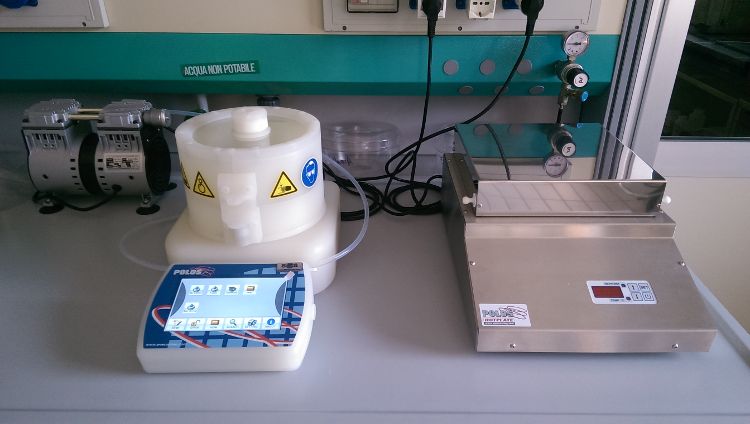

POLOS Spin150i-NPP SPS-Europe Spin coater

SPIN150i is suitable for substrates with different sizes, from small fragments down to 5 mm up to Ø =150 mm (or 6″) or 4×4″. Its main features are:

- unlimited possibility of saving programs

- suitability for all processes based on spinning: cleaning, coating, etc.

SPIN150i is specifically designed for R&D activities and low-volume production in the fields of MEMS, semiconductors, PV, and microfluidics. SPIN150i is coupled with the Polos 150 hot plate for solvent evaporation and film consolidation. The main features of the hot plate are:

- temperature range 50 – 230 °C (homogeneity ± 0.5 °C)

- heated plate size 180 x 180 mm