Dip Coater

Supervisor: Federico Veronesi

The Dip Coater is a system for coating deposition by immersion and withdrawal at a controlled velocity. Its mechanical arm can move with controlled velocity to immerse the sample attached to it into a vessel containing the liquid phase to be deposited.

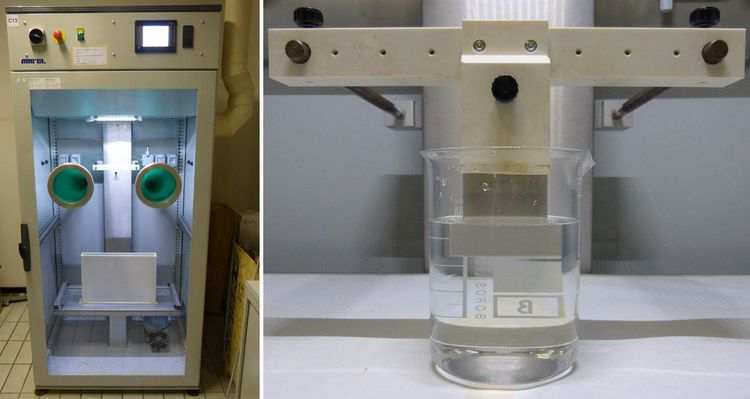

CNR-ISTEC owns a custom-made Dip Coater manufactured by Aurel S.p.A. for deposition on a pre-industrial scale. With this system, it is possible to set the starting and the final points of the arm, allowing the highest reproducibility of the deposition process. Furthermore, immersion and dripping time can be set.

In the Aurel Dip Coater, it is also possible to add a metallic countertop to perform small-scale depositions. Moreover, it is equipped with an aspiration system, plexiglas door with gloves, sockets and humidity control inside the chamber, which make it suitable as a reaction chamber.

CNR-ISTEC also has a lab-scale Dip Coater for deposition on smaller samples.

Aurel Dip Coater

- Immersion and withdrawal velocity between 0.1 and 20 mm/s

- Arm stroke 510 mm

- Maximum load 20 kg

- Control of relative humidity between 5 and 60%

Lab-scale Dip Coater

- Immersion and withdrawal velocity between 0.3 and 9.4 mm/s

- Arm stroke 233 mm

- Maximum load 200 g