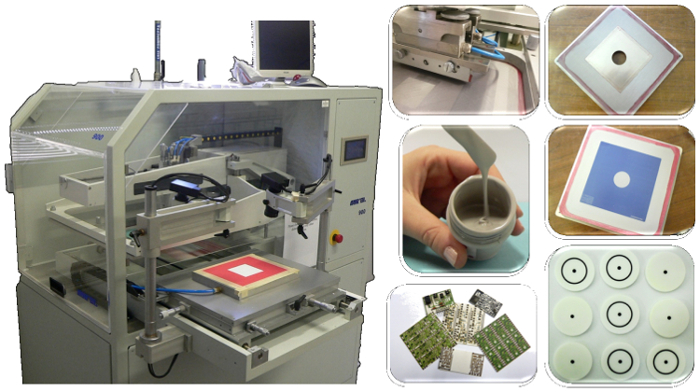

Semi-automatic screen printer

Supervisor : Alex Sangiorgi

In the advanced ceramics field, screen printing represents the main technique for the industrial production of thick films (layers with a thickness between 100 and 1 µm) for microelectronic applications (circuits, conductors, resistors, etc.). Screen printing consists of forcing, with a rubber or plastic spatula (called a doctor blade), an ink through a screen to deposit it with a predefined shape onto a support. One of the most important step of the screen printing process is the production of suitable inks, i.e. dispersions of ceramic or metallic powders in an organic or aqueous medium, for which the choice of the proper combination of the different components is a fundamental aspect in order to obtain a stable formulation over time and with the appropriate rheological characteristics.

Screen printer, Aurel 900, Aurel Automation S.p.A. (Italy)

The Aurel 900 screen printing machine is a semi-automatic device dedicated to the deposition of inks containing materials ranging from oxidic and non-oxidic ceramics (TiO2, YSZ, GDC, AlN, PZT, etc.) to glass-ceramics and, finally, metals (Ag and W).

The most important machine characteristics are:

• Maximum substrate size 200 x 200 mm

• Maximum print size 160 x 160 mm

• Maximum print speed 300 mm / s

• CCD camera system for accurate alignment of complex patterns