This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Hot Press

Supervisors : Alex Sangiorgi, Simone Failla

Hot pressing is a common way to make dense bulk ceramics, mainly in form of pellet, which involves the simultaneous application of heat and pressure. In this technique, the pressure is applied uniaxially at high temperatures. The latter term refers to a temperature where the main constituent of the sample is in the plastic deformation regime. In a conventional hot press equipment, only pressure and temperature are applied and, if the heat source is an induction furnace, the process is called inductive hot pressing.

The hot pressing process is particularly devoted to the ultra-high temperature ceramics (UHTCs) production that are materials which typically do not sinter to high densities in standard sintering operations; more recently, it is devoted to the densification of Ultra High Temperature Ceramic Matrix Composites (UHTCMCs) constituted by SiC fibres/preforms enriched with UHTCs.

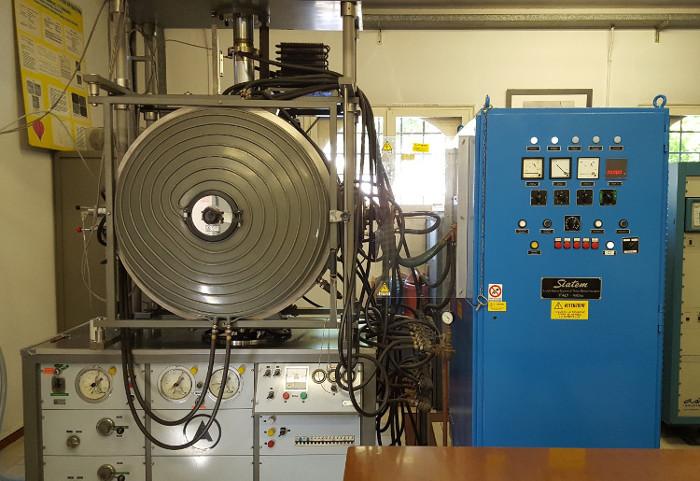

Hot Press, MP20 (II), SIATEM Padova, Ing. Allaria Alto Vuoto

The Ing. Allaria Hot Press (HP) equipment is a unique prototype particularly suitable for the production of UHTCs and UHTCMCs. The most important furnace features are:

• Maximum temperature up to 1950°C

• Maximum mechanical pressure up to 40 MPa

• Vacuum up to 10-1 mbar

• Maximum Heating rate 3000°C/h

• Heating mechanism: induction

• Temperature control system: pyrometer