This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

3D Printer

Supervisor : Alex Sangiorgi

The term 3D printing means the realization of three-dimensional objects through additive production, starting from a digital 3D model. The digital model is produced with dedicated software and subsequently elaborated using slicing software to be realized with different technologies, including Fused Deposition Modeling (FDM), Stereolitography (SLA), Selective Laser Sintering (SLS), Robocasting/Direct Ink Writing (DIW), etc.

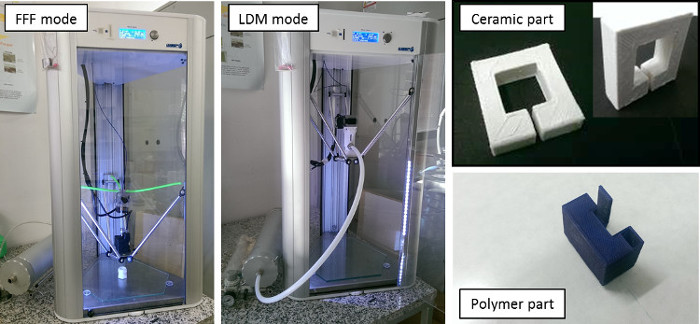

3D printer, WASP Delta 2040, CSP s.r.l. (Italy)

The Delta 2040 printer can be employed using two different configurations: the first one for the FDM (Fused Deposition Modeling) technique based on polymer filaments (PLA and ABS) micro-extrusion, and the second one (LDM), dedicated to ceramic pastes (DIW).

The most important printer features are:

• heated floor up to 100 °C

• heated nozzle up to 260°C (only in FFF mode)

• Nozzle diameter 0.4 mm in FFF mode.

• Print resolution range 0.05 mm < Res.<0.25 mm (in FFF mode)

• Maximum printing speed 300 mm/s

• Filament diameter 1.75 mm (in FFF mode)

• Filament materials ABS, PLA, PET, Nylon, Flex, Polystyrene, Laywood

• Luer Lock nozzles with variable diameter size 1600-1200-840-640-410-250-200 µm (in LDM mode)

• 3L volume Aluminum tank (for LDM mode)

• Pressure controller