This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Multi-deposition techniques station

Supervisor : Alex Sangiorgi

The possibility to couple different deposition technologies in a single station is interesting from the research and industrial point of view. This approach allows to realize simple and complex devices limiting their need of handle thus reducing their damaging and contamination and finally their costs.

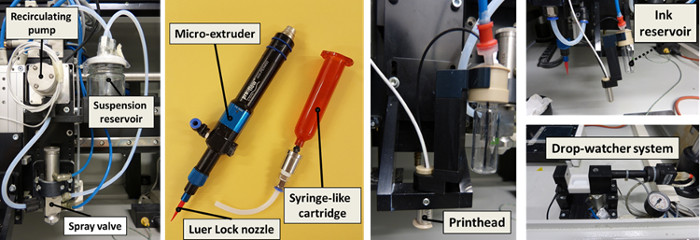

Multi-deposition techniques station, XCEL, Aurel Automation S.p.A.

XCEL is a station for spray coating (spray valve 781 RC-SS, Nordson EFD), dispensing (micro-extruder ECO-PEN 450, PreeFlow by ViscoTec) and inkjet printing (printhead MD-K-130, Microdrop).

The most important station features are:

• Substrate dimension 20×20 cm2

• X-Y axis max speed 600 mm/s, repeatability error ± 5 µm

• Z-axis max speed 50 mm/s, repeatability error ± 5 µm

• CCD camera and drop watcher system

• Compressed air up to 5 bar

• Sample holder temperature up to 250°C

Using the spray coating technique is possible to deposit wide-area layers while, using the inkjet printing or the micro-extrusion both planar and tridimensional depositions are achievable.

Brief description of each deposition apparatus:

• the low volume low pressure liquid spray valve 781RC-SS produces round patterns and stripes

• the innovative precision-volume-dispenser eco-pen 450 offers a wide range of applications for low to medium-viscosity dispensing

• the MD-K-130 dispenser head is based on piezo-driven inkjet printing technology