This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

LIGHT-TPS

Super light-weight thermal protection system for space application

Principal investigator: Laura Silvestroni

Involved personnel: Diletta Sciti, Frédéric Monteverde, Simone Failla, Daniele Dalle Fabbriche, Cesare Melandri, Claudio Capiani

Starting date: 01/05/2014

Duration: 36 months

Total funding: 1.997.363 €

Call: THEME SPA.2013.3.2-01, cooperation with third countries

Action: FP7-SPACE-2013-1-CP-FP-607182

Project Coordinator: Maria Parco (Fundacion Tecnalia Research & Innovation, Spain)

Consortium: Fundacion Tecnalia Research& Innovation (Spain), CNR-ISTEC (Italy), Frantsevich Institute for Problems of Materials Science of National Academy of Sciences of Ukraine IPMS (Ukraine), Deutsches Zentrum für Luft- und Raumfahrt DLR (Germany), ECM Space Technologies GmbH ECM (Germany), Space Research Institute SRI and National Space Agency of Ukraine NASU (Ukraine), Institute of electric welding Paton IEW (Ukraine), YUZHNOYE (Ukraine)

Official website: http://www.light-tps.eu

LIGHT-TPS (Grant agreement No. 607182) will develop a new super-light Thermal Protection System (TPS) for various space applications, above all for Reusable Space Systems (RSS), capable of operating within the entire range of working temperatures. The project aims at radical properties improvements in the TPS used existing and under-development RSS. The main disadvantage of existing TPS based on metallic frames is the significant weight and insufficient lifetime, due to the degradation and corrosion of the metal. A class of materials, commonly referred to as ultra-high temperature ceramics (UHTC) possesses a unique combination of physico-chemical properties that makes them specifically suited for application in aerospace sector. The UHTC-based coating that will be developed will provide superior oxidation protection to metal alloys, as well as to light constructions made of C/SiC and C/C materials.

The main challenge of the project is to develop a super-light, corrosion and oxidation resistant TPS by combining the advantages of metallic and ceramic materials in a single system. This will be achieved by joining a novel metallic frame with non-metallic materials (for example C/SiC and C/C), construction elements made of UHTC (system ZrB2-SiC) and new high-temperature alloys coated with UHTC composites. Particularly, the 3 directions of works are envisaged:

- development of new powder alloys on the base of Ni/Cr and Nb for the frame of TPS;

- development of reusable light weight multilayer metallic TPS sandwiches;

- investigation of erosion-resistant UHTC bulk materials in the ZrB2-SiC system and coating of metallic and non-metallic materials with the most suitable UHTC compositions.

The developed TPS will be significantly lighter than any existing TPS (under 10 kg/m2) thus reducing the cost of delivering a payload to orbit and volume of emission, guarantee reliable thermal protection in the entire range of working temperatures, possess improved mechanical and durability properties.

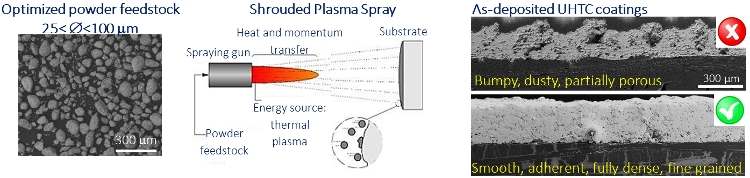

ISTEC in mainly involved in the development of bulk UHTCs and powder UHTC-based granules for the deposition of coatings on metal/non-metal substrates by shrouded plasma spray.

Insights

Publications & Patents

- F. Monteverde, L. Silvestroni, “Combined effects of WC and SiC on densification and thermo-mechanical stability of ZrB2 ceramics”, Materials & Design 109 (2016) 396–407.

- L. Silvestroni, H-J. Kleebe, W.G. Fahrenholtz, J. Watts “Super-strong materials for temperatures exceeding 2000°C”, Sci. Rep. 7, 40730; doi: 10.1038/srep40730 (2017).

- L. Silvestroni, H-J. Kleebe, “Critical oxidation behavior of Ta-containing ZrB2 composites in the 1500-1650°C temperature range”, Journal of the European Ceramic Society, 37 (2017) 1899–1908.

- L. Silvestroni, D. Sciti, F. Monteverde, K. Stricker, H-J. Kleebe, “Microstructure evolution of a W-doped ZrB2 ceramic upon high-temperature oxidation”, Journal of the American Society, 100 [4] (2017) 1760-1772.

- L. Silvestroni, S. Failla, I. Neshpor, O. Grigoriev, “Method to improve the oxidation resistance of ZrB2-based ceramics for reusable space systems”, Journal of the European Ceramic Society, 38 [6] (2018)2467-2476.

- O.N. Grigoriev, I.P. Neshpor, T.V. Mosina, V.B. Vinokurov, A.V. Koroteev, O.V. Buriachek, D. V. Vedel, A.N.Stepanchuk, L. Silvestroni, “Behavior of ultra-high temperature ZrB2-based ceramics in oxidation”, Powder Metallurgy and Metal Ceramics, 56 [9-10] (2018) 573-580.

- L Silvestroni, K. Stricker, D. Sciti, H.-J. Kleebe, “Understanding the oxidation behavior of a ZrB2–MoSi2 composite at ultra-high temperatures”, Acta Materialia, 151 [1] (2018) 216-228.

- L. Silvestroni, S. Failla, V. Vinokurov, I. Neshpor, O. Grigoriev, “Core-shell structure: an effective feature for strengthening ZrB2 ceramics”, Scripta Materialia 160 (2019) 1-4.