ADOPTIC

Additive optimisation for improved ceramics

Principal Investigator: Carmen Galassi

Involved personnel : Davide Gardini

Starting date: 01/09/2006

Duration: 36 mesi

Total funding: 1.316.782,60 €

Call: FP6- 2004-SME-COLL – GA No.030338

Action: Collective Research Projects

Coordinator: Phil Jackson (CERAM RESEARCH LTD, UK)

Consortium: 25 partners from 4 European Countries

Since September 2006 the European R&D Project ADOPTIC – Additive Optimization for Improved Ceramics – Research Collective Project (COLL-CT-2006-030338) – has started. It involves 4 European countries (Italy, United Kingdom, Portugal and Poland) and 25 partners including Research Centres and Universities (RTDs), Industrial Associations or Groups (IAGs), and Small and Medium Enterprises (SMEs). The 3-year Project aims at supplying a web Knowledge System (KS) (www.adoptic.eu) to the SMEs. In KS the users can found, with few clicks, information and answers about the ceramic processes, the additives and the faults on the pieces. The main aim is to improve the formulations of the ceramic suspensions (slips, glazes, slurries, ..) and of the plastic bodies and press-related powders in order to increase the quality of the products and the yield of the processes. The Project is based on the study of the effectiveness of the additives used in the ceramic process trough the setting up of suitable rheological protocols. The additives, although added in small amounts, strongly influence the behaviour of the suspensions, and therefore the yield of the processes and the quality of the products. Owing to the complex interactions in the multicomponent bodies the selection of additives (and their dosage) is critical and ceramic SME producers often struggle to source the best binder, deflocculant etc. as their performances, especially for the organic-based ones, are optimized for other sectors. Moreover, some trade products could be withdrawn from the market or become out-of-law due to the application of new norms as REACH. Another objective of the Project is to give help to the users into find some alternatives to the current used additives in case of need.

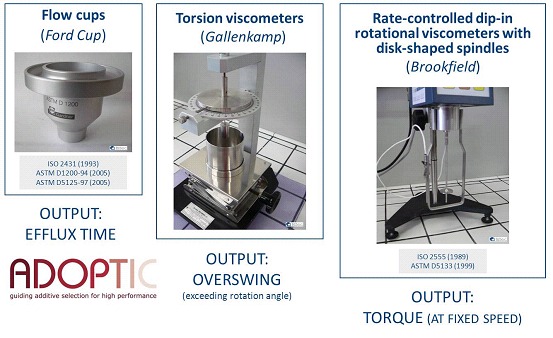

CNR-ISTEC contributes to the Project concerning the creation and the set up of the rheological protocols for the quality control and optimisation of the formulations of the ceramic suspensions, throughout the choice and the dosing of additives. Moreover, collaborates in the rationalization of the additives in order to create a flexible and updating tree diagram which can supply fast solutions in finding the most proper additives for different applications.