C3HARME

Next generation Ceramic Composites for combustion HARsh environMEnts and space

Principal investigator: Diletta Sciti

Involved personnel: Luca Zoli, Antonio Vinci, Laura Silvestroni, Fréderic Monteverde, Federico Saraga, Pietro Galizia, Simone Failla, Daniele Dalle Fabbriche, Cesare Melandri, Claudio Capiani

Starting date: 01/06/2016

Duration: 48 months

Total funding: 8,033,034.97 €

Call: RIA

Project Coordinator: Diletta Sciti

Partnership: Academia (University of Naples Federico II, University of Birmingham, Trinity College Dublin), Research centers (Consiglio Nazionale delle Ricerche – Istituto di Scienza e Tecnologia dei Materiali Ceramici, Fundación Tecnalia Research and Innovation, Deutsches Zentrum für Luft und Raumfahrt), SME (IN Srl, NANOKER Research SL, High Performance Structure Gestão e Engenharia Lda), End users (Avio S.p.A., Airbus Safran Launchers, Airbus Group Innovations)Academia (University of Naples Federico II, University of Birmingham, Trinity College Dublin), Research centers (Consiglio Nazionale delle Ricerche – Istituto di Scienza e Tecnologia dei Materiali Ceramici, Fundación Tecnalia Research and Innovation, Deutsches Zentrum für Luft und Raumfahrt), SME (IN Srl, NANOKER Research SL, High Performance Structure Gestão e Engenharia Lda), End users (Avio S.p.A., Airbus Safran Launchers, Airbus Group Innovations)

Official website: link

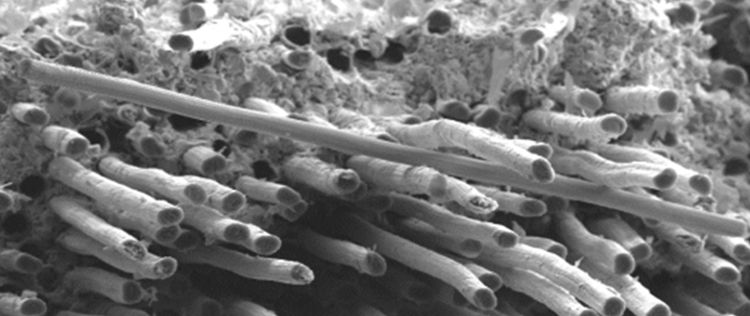

C3HARME (Grant agreement No 685594) is a research project funded under the NMP-19-2015 call of the European Union’s Horizon 2020 Framework Programme. The main purpose of C3HARME is to design, develop, manufacture, validate a new class of out-performing, reliable, cost-effective and scalable Ultra High Temperature Ceramic Matrix Composites. UHTCMCs will be based on C or SiC fibres/preforms enriched with ultra-high temperature ceramics (UHTCs) capable of in-situ repairing damage induced during operation in severe aerospace environments.

The drive behind C3HARME is the increasing demand for advanced materials with temperature capability able to withstand highly corrosive environments and having application in the aerospace sector. As a matter of fact, the combination of extremely hot temperatures (up to 2500°C), chemically aggressive environments and rapid heating/cooling conditions is beyond the capabilities of current materials. Within this framework, C3HARME will develop aerospace components, i.e. rocket nozzle inserts and thermal protection systems, able to withstand the extreme environmental conditions of launch and re-entry.

C3HARME Consortium merge a critical mass of scientific expertise and excellence in key areas (materials science, engineering, process technology, material modelling and processing, industrial scale-up). Partners integrate the whole research and innovation value chain in the life-cycle of complex thermal and mechanical subsystems of space vehicles.

Publications & Patents

- L. Silvestroni, N. Gilli, A. Migliori, D. Sciti, J. Watts, G.E. Hilmas, W.G. Fahrenholtz. A simple route to fabricate strong boride hierarchical composites for use at ultra-high temperature. In press at Composites B.

- L. Silvestroni, C. Melandri, V. Venkatachalam, J. Binner, D. Sciti. Merging toughness and oxidation resistance in a light ZrB2 composite. Materials and Design 183 (2019) 108078.

- D. Sciti, L. Silvestroni, F. Monteverde, A. Vinci, L. Zoli. Introduction to H2020 project C3HARME – Next generation Ceramic Composites for Combustion Harsh Environment and space. Advances at Applied Ceramics: Structural, Functional and Bioceramics, 117 [S1] (2018) S70-75.

- L. Silvestroni, S. Failla, A. Vinci, L. Zoli, V. Rubio, J. Binner, D. Sciti. Ablation behaviour of ultra-high temperature ceramic matrix composites: Role of MeSi2 addition. Journal of the European Ceramic Society 39 (2019) 2771–2781. L. Silvestroni, S. Mungiguerra, D. Sciti, G. D. Di Martino, R. Savino. Effect of hypersonic flow chemical composition on the oxidation behavior of a super-strong UHTC. Corrosion Science 159 (2019) 108125.

- M.A. Lagos, C. Pellegrini, I.Agote, N.Azurmendi, J.Barcena, M.Parco, L.Silvestroni, L.Zoli, D.Sciti. Ti3SiC2-Cf composites by spark plasma sintering: Processing, microstructure and thermo-mechanical properties. Journal of the European Ceramic Society, available online 16 March 2019L. Silvestroni, A.Vinci, S.Failla, L.Zoli, V.Rubio, J.Binner, D.Sciti Ablation behaviour of ultra-high temperature ceramic matrix composites: role of MeSi2 addition, Journal of the European Ceramic Society, available online 15 March 2019.

- S.Mungiguerra, G.D.Di Martino, A.Cecere, R.Savino, L.Silvestroni, A.Vinci, L.Zoli, D.Sciti Arc-jet wind tunnel characterization of ultra-high-temperature ceramic matrix composites Corrosion Science, Volume 149, 1 April 2019, Pages 18-28.

- P. Galizia, L. Zoli, D. Sciti. Impact of residual stress on thermal damage accumulation, and Young’s modulus of fiber-reinforced ultra-high temperature ceramics. Materials & Design, Volume 160, 15 December 2018, Pages 803-809.

- Vinci, L. Zoli, D. Sciti, J. Watts, G.E.Hilmas, W.G.Fahrenholtz. Mechanical behaviour of carbon fibre reinforced TaC/SiC and ZrC/SiC composites up to 2100°C. Journal of the European Ceramic Society, Volume 39, Issue 4, April 2019, Pages 780-787.

- S. Failla, P. Galizia, L. Zoli, A. Vinci, D. Sciti. Toughening effect of non-periodic fiber distribution on crack propagation energy of UHTC composites Journal of Alloys and Compounds, Volume 777, 10 March 2019, Pages 612-618,November 2018.

- Vinci, L. Zoli, D. Sciti. Influence of SiC content on the oxidation of carbon fibre reinforced ZrB2/SiC composites at 1500 and 1650°C in air. Journal of the European Ceramic Society, Volume 38, Issue 11, September 2018, Pages 3767-3776.

- L Zoli, A Vinci, P Galizia, C Melandri, D Sciti. On the thermal shock resistance and mechanical properties of novel unidirectional UHTCMCs for extreme environments. Scientific Reports volume 8, Article number: 9148 (June 2018).

- Vinci A., Zoli L., Sciti D., Cesare M. & Guicciardi S. Understanding the mechanical properties of novel UHTCMCs through random forest and regression tree analysis. Materials & Design, Volume 145, 5 May 2018, Pages 97-107 (2018).

- L. Silvestroni, K. Stricker, D. Sciti, H.J. Kleebe. Understanding the oxidation behavior of a ZrB2-MoSi2composite at ultra-high temperatures. Acta Materialia, March 2018.

- P. Galizia, S. Failla, L. Zoli, D. Sciti. Tough salami-inspired Cf/ZrB2 UHTCMCs produced by electrophoretic deposition Journal of the European Ceramic Society, Volume 38, Issue 2, February 2018, Pages 403-409.

- Zoli L, Galizia P, Silvestroni L, Sciti D. Synthesis of group IV and V metal diboride nanocrystals via borothermal reduction with sodium borohydride. J Am Ceram Soc. 2018;00:1–11 First published: 21 December 2017.

- L. Zoli, A. Vinci, L. Silvestroni, D. Sciti, M. Reece, S. Grasso. Rapid spark plasma sintering to produce dense UHTCs reinforced with undamaged carbon fibres. Materials and Design, Volume 130, 15 September 2017, Pages 1-7.

- A.Vinci, L. Zoli, E. Landi, D. Sciti. Oxidation behaviour of a continuous carbon fibre reinforced ZrB2–SiC composite. Corrosion Scienc,Volume 123, 15 July 2017, Pages 129–138 (Open Access).

- L. Zoli, D. Sciti. Efficacy of a ZrB2 – SiC matrix in protecting C fibres from oxidation in novel UHTCMC materials. Materials & Design 113 (January 2017).