This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Synthesis of nanostructured ceramics for sever applications

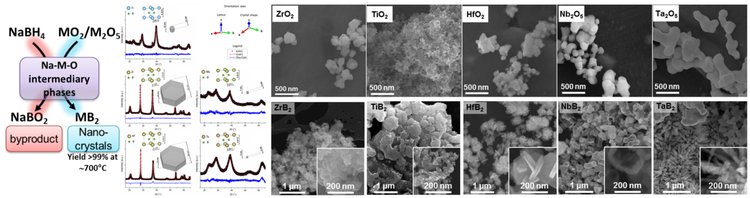

Nanometric transition metals borides powders

Principal investigator: Luca Zoli

Ivolved personnel: Diletta Sciti, Pietro Galizia, Laura Silvestroni, Paola Pinasco, Andreana Piancastelli

Ultra-refractory ceramics (Ultra High Temperature Ceramics), such as borides and carbides of transition metals, are promising materials for applications in harsh environments, in aerospace industry and in the nuclear industries as thermal protection, in the solar field, as solar energy absorbers , in transport as disc brakes. UHTCs have very advantageous properties, such as very high melting points or good high temperature thermo-mechanical properties, which can be exploited to increase the operating temperatures of the components.

The sintering process from commercial ceramic powders requires very high temperatures. Nanostructured powders with a high specific surface area of transition metal borides offer several advantages:

- high reactivity during sintering;

- increased stability of ceramic suspensions;

- specific morphologies of the particles (flat, needle-like, hollow spheres).

CNR-ISTEC realizes these powders starting from sodium borohydride and oxides of the transition metals and treatment at temperatures <1000 ° C.

Equipment & Processes

- Powder mixing

- Inert gas heat treatment in tubular furnace

- Specific surface analysis

- Determination of the size of the X-ray grains

Main collaboration

- University ofl North Carolina

- AIRBUS Research Centre

- Tecnalia

Projects

Publications & Patents

- L. Zoli, A.L. Costa, D. Sciti, Synthesis of nanosized zirconium diboride powder via oxide-borohydride solid-state reaction, Scr. Mater. 109 (2015) 100–103.

- L. Zoli, P. Galizia, L. Silvestroni, D. Sciti, Synthesis of group IV and V metal diboride nanocrystals via borothermal reduction with sodium borohydride J Am Ceram Soc, 101 (6), (2018) 2627-2637. doi: 10.1111/jace.15401