This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Multifunctional ceramic composites

Ceramic-ceramic and ceramic-metal composites

Principal investigators: Diletta Sciti, Valentina Medri, Frédéric Monteverde

Personale coinvolto: Laura Silvestroni, Luca Zoli, Cesare Melandri, Claudio Capiani, Andreana Piancastelli

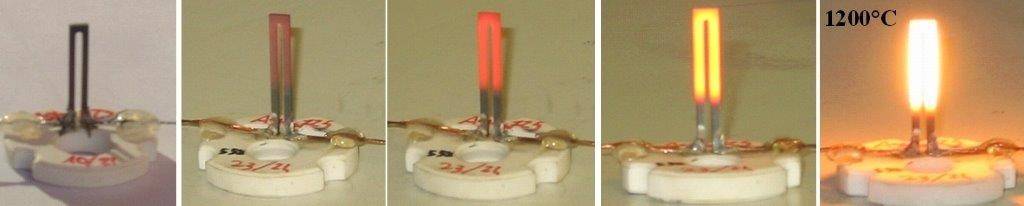

The development of electrically conductive ceramic composites with good high-temperature structural properties is of great interest for a wide range of applications. Composites made of insulating ceramics (such as alumina, silicon nitride, aluminium nitride, silicon carbide ) and variable amounts of electro-conductive phases (metallic, intermetallic or ceramic) can fulfil these requirements.

The following composites are produced and studied at ISTEC:

- Si3N4-TiN, Si3N4-MoSi2

- AlN-SiC-MoSi2, AlN-SiC-ZrB2, AlN-SiC-ZrC

- Al2O3-TiC, Al2O3-TiB2, Al2O3-TiN, Al2O3-Mo, Al2O3-NiAl.

These composites are currently employed in applications as heaters or igniters. The addition of a “lubricant” secondary phase such as h-BN allows for high machinability. Cermets (ceramic-metal composites) based on TiCN-WC-Ni-Co and WC-Co hard metals are also studied as cutting tools. In this regard, the POR-FESR HI-Score project aims at the reduction of energy consumption during machining, the replacement of cutting oils with cryogenic fluids and the study of ceramic materials for cutting tools. Characteristics like

- sintering behaviour

- microstructure

- electrical resistivity

- thermo-mechanical properties at room and high temperature

are investigated.

Equipment and processes

- Hot pressing furnace

- Controlled atmosphere furnaces (Tmax: 2400°C)

- Tribometer

- Microhardness indenter

- Nanoindenter

- Universal machines for mechanical testing (Tmax: 1500°C)

Main collaboration

- Consorzio MUSP- Macchine Utensili e Sistemi di Produzione

- Piacenza, Italia

- Instituto de Ciencia de Materiales de Sevilla

- Centro Mixto CSIC-US, Sevilla, Spain

Projects

Publications & Patents

- Chicardi, F.J. Gotor, V. Medri, S. Guicciardi, S. Lascano, J.M. Córdoba, Hot-Pressing of (Ti, Mt)(C, N)-Co-Mo2C (Mt=Ta, Nb) powdered cermets synthesized by a mechanically induced self-sustaining reaction, Chemical Engineering Journal 292 (2016) 51–61.

- Chicardi, Y. Torres, M.J. Sayagués, V. Medri, C. Melandri, J.M. Córdoba, F.J. Gotor, Toughening of complete solid solution cermets by graphite addition, Chemical Engineering Journal 267 (2015) 297–305.

- J. Gotor, R. Bermejo, J.M. Córdoba, E. Chicardi, V. Medri, D. Dalle Fabbriche, Y. Torres, Processing and characterisation of cermet/hardmetal laminates with strong interfaces, Materials and Design 58 (2014) 226–233.

- J. M. Córdoba, E. Chicardi, R. Poyato, F. J. Gotor, V. Medri, S. Guicciardi, C. Melandri, Spark plasma sintering of TixTa1_xC0.5N0.5-based cermets: Effects of processing conditions on chemistry, microstructure and mechanical properties, Chemical Engineering Journal 230 (2013) 558–566.