This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Hierarchically organized scaffold for load bearing bone

Biomorphic transformation of natural templates

Principal investigators: Anna Tampieri, Simone Sprio, Andrea Ruffini

Personnel involved: Silvia Panseri, Monica Montesi

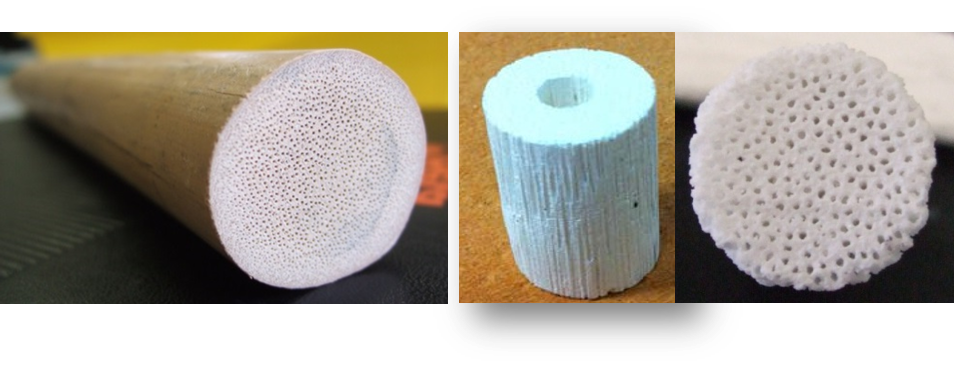

This research develops biomorphic transformations as a new method to fabricate 3-D bioceramic scaffolds featuring high bioactivity and hierarchic structure at the base of superior mechanical performance. Biomorphic transformations convert natural structures, selected for their functionally relevant structural features, into biomimetic calcium phosphates that, for their excellent mimicry of compositional, morphological and mechanical properties of long bone tissue, can be applied to substitution of large load-bearing bone segments. The fabrication method is based on a pyrolysis process aimed at eliminating the organic components of the bio-structure and obtain a carbon template, then subjected to heterogeneous reactions at the interface with gaseous reactants to achieve controlled phase changes whereas maintaining the original structure at the multi scale. The final apatitic scaffold is obtained by wet processes inducing controlled ion exchange enabling formation of calcium phosphates presenting various ionic substitutions enhancing osteogenesis and bio-resorption. The nanostructure and multi-scale hierarchy are at the base of superior and bone-like mechanical performance that are promising to withstand early biomechanical loading after implantation and activation of mechanotransduction processes at the base of bone remodeling.

The long-lasting collaborations with companies active in the biomedical field is a strong driver for the development of new biomaterials and devices for solving clinical needs of relevant socio-economic impact. In particular, regeneration of load bearing bones is a critical need still not solved and today managed by complex and repeated surgery with high societal costs and relevant patient morbidity.

The technology based on biomorphic transformations originated by a EU-funded project (TEM-PLANT), coordinated by ISTEC and today is subjected to a technology transfer process to an innovative start-up (GreenBone Ortho srl, Faenza, Italy) for the achievement of a proof of concept of effective regeneration of load-bearing bones in clinical cases. This research generated two international patents now filed at a world level.

Equipment and processes

Equipment

- Furnaces operating at low gas pressure or vacuum

- Autoclaves

Processes

- Gas-solid reactions at tailored gas mixtures and pressures

- Hydrothermal reactions

Main collaborations

- GreenBone Ortho srl,

- Università di Trento,

- Istituti Ortopedici Rizzoli,

- CNR-NANO,

- Università di Ferrara,

- Finceramica Faenza SpA.