Smart filters for gas and liquids

Principal investigators: Monica Sandri, Anna Tampieri

Personnel involved: Elisabetta Campodoni, Chiara Artusi

3D devices with a controlled porosity are developed through nature-inspired processes; these processes develop smart and multifunctional composites made of polymeric and hybrid materials through mineralization reaction and self-assembling of polymeric structures.

In the same way, in laboratory nature-inspired processes as well as a detailed choice and combination of different polymeric and inorganic phases have been exploited to develop porous devices suitable in different environments such as gaseous, aqueous, organic solvent and capable to filter different materials:

- Metallic and non-metallic nano- and micro-particles for innovative respiratory filters in military field (Military Defense financially supported this project).

- Particles and bacteria in environmental field (e.g. water purification).

- Water vapour in medical field such as HMEf for tracheotomised patients. These devices are capable to create a balance between humidity expired and inspired from patient recycling heat and moisture exhaled form the patient and deliver them during the next inspiration to the incoming dry and cold medical gases. Furthermore, these devices are endowed with bacteriostatic power for a major safety of the patient.

They are featured by high porosity due to freeze-drying technique which establishes the ice crystals’ geometry in growing by means of freezing and drying ramp highly controlled. The modulation of these process parameters influences, in a strictly controlled way, size and morphology of ice crystals which are converted in porosity during drying phase. Freeze-drying process allows to control the capture ability together with gaseous and liquids’ pressure drop.

- HME filters (heat and moisture exchange) for tracheotomised patients

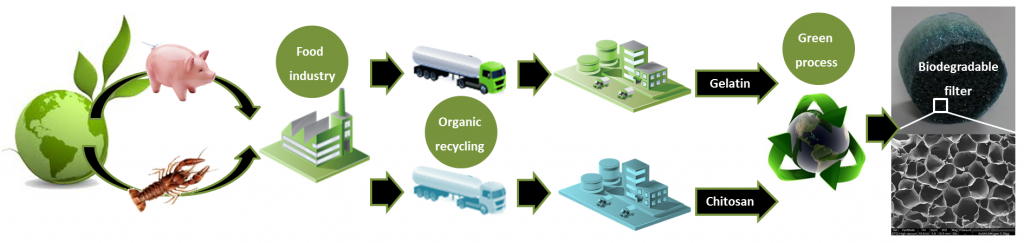

By taking inspiration from nature and through an environmental friendly chemical process we were able to design and develop innovative HME devices endowed with excellent moisture output, low pressure drop and antimicrobial properties. In detail, HME devices are composed of gelatin and chitosan which were selected as promising economical candidates for the development of bio-polymeric matrices mimicking the moisturizing function of mucus and suitable for the development of HME devices.

The development of a cross-linked blend gives higher mechanical and chemical stability to the dried porous structure in dry and wet environment. The highly aligned morphology bestows on HME filters a big superficial area and a low pressure drop suitable to mimic the “natural noise” able to recycle the heat and humidity exhaled from the patient. Finally, raw materials are by-product of food industry, largely available as well as a low price, suitable to achieve a biodegradable, biocompatible and cheap device through a simple and environmentally friendly chemical process attaching importance to “waste recycling”. - Filters for nanoparticles and bacteria capture A biologically-inspired mineralization process is exploited to achieve a filter composed of gelatin mineralized with hydroxyapatite (HA) featured by interconnected porosity suitable to show a low pressure drop. Furthermore, a high capture nanoparticle ability up to 30-100 nm, hardly arrested with other devices, is obtained thank to a suitable pore size, to the presence of hydroxyapatite which can be interact with toxic substance and heavy metals and to the organic phase which creates a multi-dimensional porosity without increasing the pressure drop. Finally, devices can be customized adding colloidal silver nanoparticles to assure a bacteriostatic activity after bacteria capturing.

Equipment and processes

Advanced techniques are exploited to develop devices featured by a complex porosity. In detail, for the synthesis biologically-inspired process are used, while cold processes ( e.g. freeze-drying, salt leaching, tape casting) allow to create the 3D macrostructure with high porosity.

Main collaborations

- Pollution Bologna

- CNR ISAC e ISOF Bologna

- Università di Ferrara, microbiologia

- Friedrich-Schiller-University of Jena, Germany

Projects

Publications & Patents

- 102017000022625: FILTRO PER LO SCAMBIO DI CALORE E UMIDITÀ PER APPLICAZIONE IN CAMPO MEDICALE E PROCEDIMENTO PER LA SUA PRODUZIONE

Inventors: Sandri Monica, Sprio Simone, Tampieri Anna

Registration date: 28/02/2017