Bio-inert bulk structural ceramics

Design, development and characterization of bio-inert structural ceramics and composites for dental and prosthetic applications

Principal investigators: Frédéric Monteverde, Elena Landi, Valentina Medri

Involved personnel: Federico Saraga, Cesare Melandri

Bio-inert bulk structural ceramics are designed, developed and characterized to improve their in service performance.

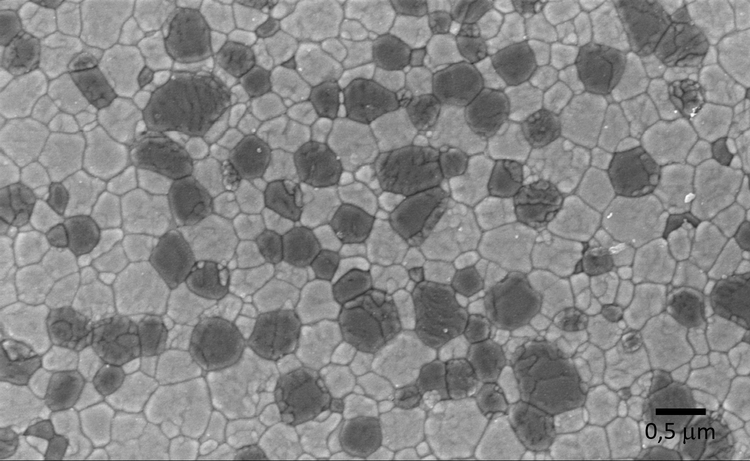

“Multi-domain” ceramics based on zirconia, alumina and their composites are produced through well-known dry/wet mixing procedures, cold isostatic pressing and sintering using conventional air furnaces, to determine their comparative performances

The achievement of a good combination of performances for flexural strength, fracture toughness or hardness cannot be separated from the ability of the same materials/devices to interact properly with the physiological environment. Therefore, various functionalizations (laser micro-machining, micro-sandblasting, chemical leaching) and their impact on aging, cytotoxicity and osteointegration are studied.

New concepts are constantly taken into consideration, such as multi-layer structures with variable density, i.e. structures with multi-dimensional hierarchical porosity, for a better osteo-integrability.

The customization of the devices always represents the handover from the laboratory environment with simple forms. Therefore, the realization of bulk ceramics loaded with electro-conductive bio-inert components capable of making electro-erodible, and therefore shapeable, oxide-based composites for total and partial prosthetic reconstructions of articulations and near zero wear articular surfaces are studied and developed.