This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Ceramic fabrics

Antibacterial-antivirial, anti-flame, photocatalytic treatments

Principal investigator: Simona Ortelli

Involved personnel: Magda Blosi, Carlo Baldisserri, Andrea Brigliadori, Anna Luisa Costa, Antonio Crimaldi, Lara Faccani, Davide Gardini, Marina Serantoni, Felice Carlo Simeone, Ilaria Zanoni

The functionalization of fabrics, through the application of nanostructured coatings, allows the creation of new materials in which the properties of the nanoparticles that make up the coating are transferred to the fabrics. The nanometric dimensions make the particles transparent to visible light so their presence does not alter the colour. The nanostructured coating has a remarkable affinity for fabrics, does not alter the sensation of contact with the skin, its breathability and resists many washes.

In order to obtain a product with the desired functional properties it is necessary to follow an iterative study that includes:

- accurate chemical-physical characterization of the suspension containing the nanoparticles (nanosuspension)

- morphological characterization and identification of the nature of the fabric

- identification of the method of application of the coating on the substrate

- study of the degree of adhesion of the coating on the support, through morphological analysis and release tests

- morphological and physico-chemical characterization of the final system

- evaluation of functional properties

A complete study allows to maximize the integration between coating and fabric, to optimize the entire process and consequently improve the final functional properties of the material obtained.

Antimicrobial / antiviral coatings

Materials

• Ag-HEC, Ag-Cellulose, Ag-Biopolymers: suspensions based on nanoparticle Ag immersed in cellulosic or biopolymeric matrices for the treatment of fabrics that thus acquire antibacterial / antiviral properties. (link pagina sol gel)

Applications

Antibacterial and antiviral fabrics tested for their excellent performance in the control of bacterial (Gram positive and negative) and viral (SARS-CoV 2) infections.

Fireproof coatings for fabrics

Materials

• TiO2 @ biomachromelecules, the ceramic layer based on TiO2 nanoparticles acts as a physical protection and as a support to biomacromolecules (whey proteins, casein, DNA etc.) which behave as flame-retardant intumescent materials

• Ceramers (organic / inorganic hybrids) create a barrier effect, protecting the underlying material from flames and heat sources.

Applications

• Flame retardant fabrics, characterized by good washing fastness and excellent flame-retardant properties, reaching, in the case of coatings based on TiO2@casein and TiO2@DNA, the self-extinction.

• Fabrics with high thermal stability.

Photocatalytic coatings

Materials

• TiO2

• TiO2@SiO2 (Nanotechnologies applied to water purification)

• TiO2@microalgae (Chlorella Vulgaris, Spirulina) composites able to couple the photocatalytic properties of TiO2 to the biosorbent ones with respect to heavy metals, typical of biomass.

• Using a suspension, it is possible to impregnate surfaces such as fabrics, membranes, and possibly add TiO2 / biomass also to polymers for electrospinning

• Hydrotalcite-like compounds (HTlc): layered double hydroxides of MII (ie Mg, Zn) and MIII (ie Al, Fe), characterized by adsorbent and anionic exchange properties, useful as photoactive doped semiconductors in UV-VIS range

Applications

• photocatalytic treatments for the oxidation of polluting molecules (Nanotechnologies applied to water purification)

• processes of absorption of pollutants (Nanotechnologies applied to water purification)

Instruments

• bench dip coating

• spray coating

Processes

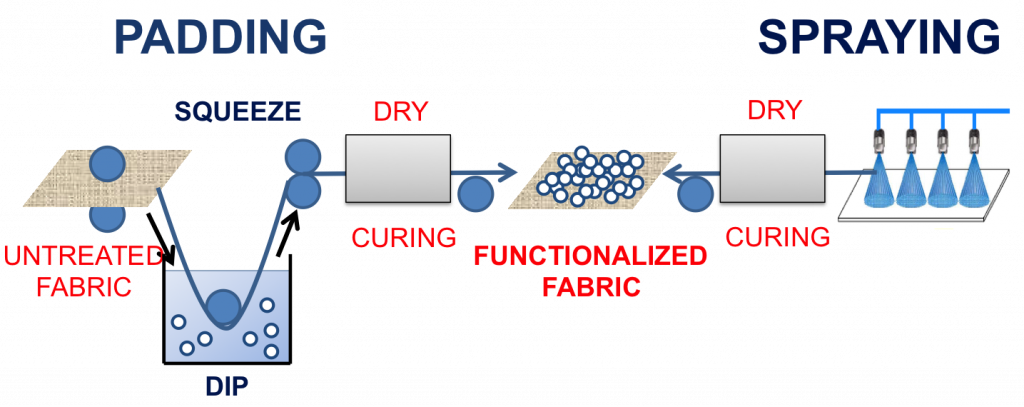

The dip-padding-curing process of the fabric consists of three phases:

- immerse the entire fabric in the nanosuspension

- squeeze the fabric to remove excess

- subject the fabric to a heat treatment in the stove, to facilitate adhesion to the support.

This method is suitable for scale-up, with a view to industrialization of the process.

Main collaborations

Dr. Alessio Varesano, Dr. Claudia Vineis, CNR-STIIMA

Prof. Giulio Malucelli, Politecnico di Torino

Dr Antonio Andretta, Klopman International S.r.l.

Dr. Juliana Oliveira e Dr. Nuno Azoia, CeNTI – Centre for Nanotechnology and Smart Materials

Projets

Pubblications and patents

- S. Ortelli, A.L. Costa, Insulating Thermal and Water-Resistant Hybrid Coating for Fabrics, Coatings, 10 (2020) 72

- S. Ortelli, G. Malucelli, M. Blosi, I. Zanoni, A.L. Costa, NanoTiO2@DNA complex: a novel eco, durable, fire retardant design strategy for cotton textiles, Journal of Colloid and Interface Science, 546 (2019) 174–183

- S. Ortelli, G. Malucelli, F. Cuttica, M. Blosi, I. Zanoni, A.L. Costa, Coatings made of proteins adsorbed on TiO2 nanoparticles: a new flame retardant approach for cotton fabrics, Cellulose 25 (2018) 2755–2765

- S. Ortelli, A.L. Costa, M. Dondi, TiO2 nanosols applied directly on textiles using different purification treatments, Materials 8 (2015) 7988–7996

- Varesano, C. Vineis, C. Tonetti, D.O. Sanchez Ramirez, G. Mazzuchetti, S. Ortelli, M. Blosi, A.L. Costa, Multifunctional Hybrid Nanocomposite Nanofibers Produced by Colloid Electrospinning from Water Solutions, Current Nanoscience 11 (2015) 41–48

- M. Blosi, S. Albonetti, M. Dondi, G. Baldi, A. Barzanti: “Process for preparing stable suspensions of metal nanoparticles and the stable colloidal suspensions obtained thereby” PCT/EP2010/052534 WO 2010/100107

- A.L Costa, M. Blosi, Process for the preparation of nanoparticles of noble metals in hydrogel and nanoparticles thus obtained, WO/2016/125070