This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Synthesis and deposition of coatings for wetting control

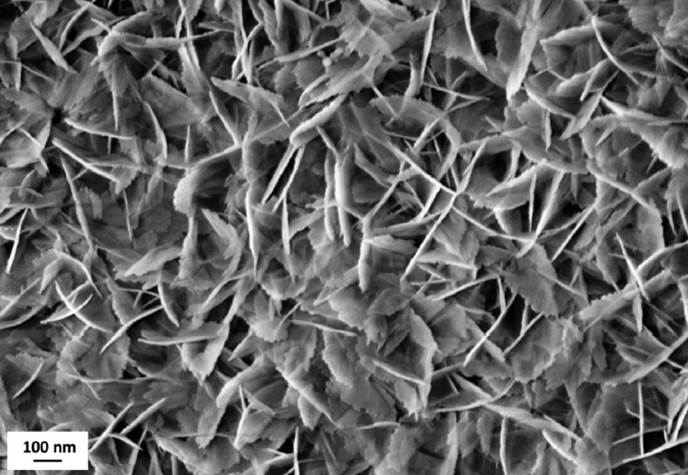

Ceramic and hybrid nanostructured coatings with self-cleaning properties

Principal Investigators: Mariarosa Raimondo, Magda Blosi, Federico Veronesi

Involved personnel: Alessandro Corozzi, Guia Guarini

The research activity aims at the design, synthesis, and deposition of ceramic or hybrid coatings (ceramic and organic) for the control of surface wetting properties.

To reach this target, it is necessary to modulate coating morphology, introducing a surface structure on the nano- and micro-scale. The durability of coating properties through time and their resistance in harsh conditions, e.g. high pressure, also depend on coating morphology.

Moreover, the surface chemical composition of the coating can be modified to achieve the desired wetting behavior. Coatings can show different wetting behaviors:

- Superhydrophilicity (water contact angle WCA < 5°)

- Superhydrophobicity (WCA > 150°) with low water drop adhesion (contact angle hysteresis CAH < 10°)

- Oleophobicity (contact angles with low surface tension liquids > 90°)

- Amphiphobicity, i.e. combination of superhydrophobicity and oleophobicity

These properties generate the self-cleaning capability of these surfaces, hindering the accumulation of dirt and easing its removal. The mechanism for self-cleaning depends on surface wetting behavior (e.g. formation of a water film on a superhydrophilic surface, dirt removal by rolling drops on superhydrophobic surfaces).

Equipment and Processes

Coatings are fabricated via sol-gel synthesis of ceramic oxide nanoparticles (alumina, silica, titania, and others) and deposited with processes like dip coating, roller printing, and automated spray coating. The process includes steps that allow the formation of a nanostructured coating with wetting properties that differ from those of the uncoated material. Film thickness ranges from hundreds of nanometers to microns, depending on the adopted process parameters.

The coating fabrication process must be tailored to the characteristics of the material to be coated, e.g. considering its sensitivity to acidic and corrosive environments or its resistance to high temperatures. Among the materials treated during the research activity:

- Metals like aluminum and copper

- Alloys like steel and brass

- Glasses of various composition (soda-lime, borosilicate, ceramic glasses)

- Ceramics (stoneware, porcelain) with different surface finishing (glazed or not)

- Natural fibers (cotton)

- Polymeric films (polystyrene)

Main collaborations

- Università degli Studi di Roma “La Sapienza” (Prof. Robertino Zanoni)

- Università degli Studi di Pavia (Prof. Vittorio Berbenni)

- Politecnico di Milano (Prof. Andrea Ratti) and Politecnico di Torino (Dr. Sara Ferraris)

- Università degli Studi di Ferrara (Prof. Gian Luca Garagnani) and Università degli Studi di Modena e Reggio Emilia (Prof. Sergio Valeri)

Projects

Publications and patents

- F. Veronesi, G. Boveri, M. Raimondo, Amphiphobic nanostructured coatings for industrial applications, Materials, 12, 787 (2019), DOI: 10.3390/ma12050787

- M. Raimondo, F. Veronesi, G. Boveri, G. Guarini, A. Motta, R. Zanoni, Superhydrophobic properties induced by sol-gel routes on copper surfaces, Applied Surface Science, 422, 1022–1029 (2017), DOI: 10.1016/j.apsusc.2017.05.257

- I. Malavasi, F. Veronesi, A. Caldarelli, M. Zani, M. Raimondo, M. Marengo, Is a knowledge of surface topology and contact angles enough to define the drop impact outcome?, Langmuir 32, 6255 − 6262 (2016), DOI: 10.1021/acs.langmuir.6b01117

- A. Motta, O. Cannelli, A. Boccia, R. Zanoni, M. Raimondo, A. Caldarelli, F. Veronesi, A mechanistic explanation of the peculiar amphiphobic properties of hybrid organic−inorganic coatings by combining XPS characterization and DFT modeling, ACS Applied Materials and Interfaces, 7, 19941 – 19947 (2015), DOI: 10.1021/acsami.5b04376

- A. Caldarelli, M. Raimondo, F. Veronesi, G. Boveri, G. Guarini, Sol-gel route for the building up of superhydrophobic nanostructured hybrid-coatings on copper surfaces, Surface & Coatings Technology 276, 408 – 415 (2015), DOI: 10.1016/j.surfcoat.2015.06.037

- M. Raimondo, M. Blosi, A. Caldarelli, G. Guarini, F. Veronesi, Wetting behavior and remarkable durability of amphiphobic aluminum alloys surfaces in a wide range of environmental conditions, Chemical Engineering Journal 258, 101 – 109 (2014), DOI: 10.1016/j.cej.2014.07.076

- Method for the treatment of metal surfaces for bestowing thereon a high hydrophobicity and oleophobicity, WO 2013/190587

- Method for the treatment of ceramic surfaces for bestowing thereon a high hydrophobicity and oleophobicity, WO 2012/117386