This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

EEE-CFCC

Evolution economically and ecologically sustainable of fiber-reinforced ceramic matrix composite with a complex shape

Principal Investigator: Valentina Medri

Personnel involved: Annalisa Natali Murri, Elettra Papa, Elena Landi, Cesare Melandri, Claudio Capiani

Starting date: 01/04/2016

Duration: 24 months

Total funding: 879.000 €

Action: POR-FESR Emilia Romagna 2014/2020 – ASSE 1 – Research and Innovation, Action 1.2.2

Project Coordinator: Claudio Mingazzini (ENEA-TEMAF)

Consortium: ENEA-TEMAF (Faenza, RA), CNR -ISTEC, CertiMaC Soc. Cons. a r.l. (Faenza, RA), CIRI-MAM (Faenza, RA), Romagna Tech S.c.p.a. (Faenza, RA)

Involved companies: RI-BA Composites srl (Faenza, RA), Curti Costruzioni Meccaniche SpA (Castel Bolognese, RA), Edilteco SpA (San Felice Sul Panaro, MO), Tampieri Energie srl (Faenza, RA).

Official website: www.eee-cfcc.it

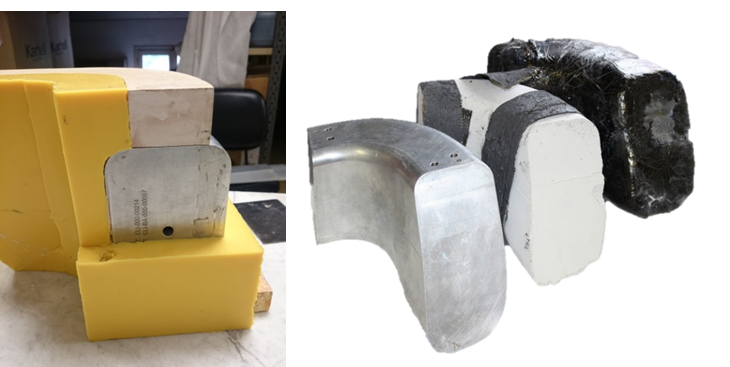

The project will develop a new fiber-reinforced ceramic material composite for the transport and construction sectors. EEE-CFCC will carry out the results obtained within the MITAI Laboratory, namely the development of a new ceramic composite (CMC) called BasKer to recall the nature of ceramic reinforced with basalt fibers. BasKer has production costs comparable to those of a polymeric composite and is able to combine a low specific weight (<2 g/cm3) with high thermostructural performances up to 600-800 ° C, ensuring fire resistance and thermal insulation up to at 1200 °C.

Polymeric composites (PMC), typically used for lightening in the transport sector, are not applicable to temperatures above 250 °C, such as in the vicinity of the engine or the braking system: the only solution to relieve the components at high temperatures is the introduction of light thermostructural inorganic materials, i.e. thermal insulation materials, which act as thermal protection against thermolable PMC.

The objective is a TRL6 for the production of both complex components in Basker and Basker + PMC, as well as fire resistant insulating panels, obtained also by using second raw materials such as PMC pyrolysis basalt felt. To achieve these goals, geopolymers will develop to provide (1) thermostructural molds for complex shapes and (2) fire resistant porous insulators, exploiting various types of industrial waste including biomass ashes and recycled carbon fibers. Materials end-of-life solutions and the LCA of materials and processes will be also studied.

Publications and patents

- Natali Murri, A., Medri, V., Papa, E., Laghi, L., Mingazzini, C., Landi, E., Porous Geopolymer Insulating Core from a Metakaolin/Biomass Ash Composite, Environments, 2017, 4 (4): 86

- Landi, E., Medri, V., Natali Murri, A., Bandini, S., De Aloysio, G., Laghi, L., D’Angelo, E., Giorgini, L., Zattini, G., Bernardelli, P., Fabbri, P., Mingazzini, C., Scafè, M., Bezzi, F., Compositi ceramici, nuova frontiera per edilizia e trasporti, Econerre (online), 2018

- Fabbri, P., Magnani, G., Mazzanti, F., Mingazzini, C., Scafè, M., Landi, E., Medri, V., Natali Murri, A., Bandini, S., De Aloysio, G., Laghi, L., D’Angelo, E., Giorgini, L., Zattini, G., Caretti, D., Nanni, D., Bernardelli, P, Compositi a matrice ceramica, ottenuti da prepreg, per tubi di scarico e paracalore, Compositi Magazine, 2018, 47:38-45

- Giorgini, L. D’angelo, E., Zattini, G., Laghi, L., Bandini, S., D’Aloysio, G., Medri, V., Landi, E., Natali Murri, A. Mingazzini, C., Fabbri, P., Bezzi, F., Mazzanti, F., Scafè, M., Bernardelli, P., Fire resistant low cost inorganic ceramic composites, Composite solutions, 12[1] (2018) 12-15.