This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

Innovative solution for the preservation of cultural heritage – Mortars

Lime hydraulic mortars (CL and NHL) for restoration interventions

Principal Investigator: Michele Macchiarola

Personnel involved: Francesca d’Aniello, Sabrina Gualtieri, Francesca Gambino

The research activity is dedicated to the development of low-carbon mortars, compatible with cultural heritage, with high durability, not particularly expensive, appropriately formulated according to the required restoration function.

They can be used to the archaeological-architectonic restoration, for the renovation of historical building for example in the structural reinforcement of barrel vaults, or for the setting of new screeds, or to install new floors, or simply to obtain lightweight plasters and thermal insulators.

Starting from Putty Lime (CL 90-SPL) and Natural Hydraulic Lime (NHL), through a suitable selection of admixtures / additives and selected aggregates, hydraulic mortars have been developed and applied with specific physical-mechanical characteristics according to the required function: for bedding, for setting of finishing, for injection, for plastering, for filling of lacunae, etc.

The technology uses inorganic raw materials typical of the historical building, through which to realize, with appropriate formulations, products that reproduce from the chemical-physical point of view the components of the archaeological / architectural wall structures or of the historical artefacts. The characteristics of the raw materials, the almost total absence of soluble salts and the porosity similar to that of the ancient materials make them compatible with the historical artefact. Furthermore, their preparation and application does not create problems for the health of the operator, and at the same time they are particularly environmentally friendly.

The extreme versatility of lime mortars, easily obtainable, through the exact dosage of binder, aggregates and admixtures (materials with pozzolanic activity, fibers and lightweight materials) allows the development of tailor-made intervention technologies. In addition, the use of particular “admixtures” such as meta kaolin in the formulation of these mortars allows to achieve mechanical properties comparable to cement ones, thus making these mortars appealing to the widest and richest market in building, bio-building and renovation. Very small and simple variations in the mix design allow to obtain different physical and mechanical properties both during setting up and hardening phases, opening new horizons for the bio-building and for the rich sector of the building renovation.

Processes & Equipment

According to the Italian standard UNI 11488:2013 “Guide lines for the classification, for the identification of the composition and for the valuation of the performance characteristics of the restoration mortars”, restoration mortars for masonry, for setting of finishing and for injection have been recently developed:

- As regards the restoration mortars, putty lime (CL90-S PL) as binder and meta kaolin plus appropriate sands as aggregates were used.

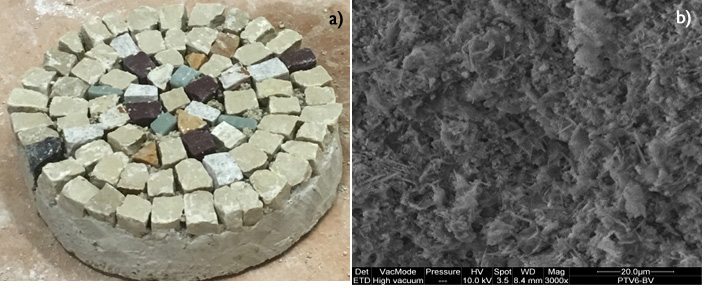

- By using NHL 3.5 (binder) and meta kaolin, other mortars were developed and successfully applied as bedding for mosaic fragments previously lifted and re-laid on new mobile supports, both traditional (e.g. Aerolam) and innovative (e.g. geopolymer panels).

- The injection mortars (NHL 3.5 and meta kaolin) have proved completely competitive, often better, in terms of performance with the premixed ones currently on the market used for this function, which generally, unfortunately, contain a cement component more or less abundant.

At the moment we are studying:

- lightweight mortars (sometimes also reinforced) composed of NHL and meta kaolin to be used as mobile support in the restoration of mosaic fragments previously lifted;

- mortars based on putty lime and meta kaolin as bedding for mosaics without the original mortar, or to which, for a better conservation, the cement bedding mortar, applied in previous restoration works, has been completely removed.

Main collaborations

• CertiMac – Faenza

• Accademia Belle Arti – Napoli

• Accademia Belle Arti – Como

• Università degli Studi di Bologna, Beni Culturali

Projects

• Mitai Linea 4