Geopolymers for process engineering

Hierarchically porous materials, sorbents, membranes and oxygen carriers

Principal investigators: Elena Landi, Valentina Medri, Francesco Miccio, Annalisa Natali Murri, Elettra Papa

Involved personnel: Cesare Melandri, Andreana Piancastelli

The activity of CNR-ISSMC is dedicated to the development of geopolymer matrices and composites for chemical engineering applications such as:

- Filtration and remediation;

- composite membranes;

- CO2 selective adsorption;

- Chemichal Looping Combustion;

- catalysis (tar reforming);

- wiking.

Geopolymers are synthetic inorganic polymers based on alluminosilicates or phosphates chemically bonded at T <300 ° C. Depending on their composition, alkali geopolymers are the amorphous-semicrystalline equivalent of crystalline zeolites. In addition to an intrinsic meso-porosity, micro-meso-macro-ultra-macro porosity may be suitably varied by means of foaming techniques. Particularly for porous geopolymeric materials, four types of products can be identified:

- mesoporous particulate composites with microporous (zeolithic) or macroporous aggregates, or functional metallic oxide;

- mesoporous geopolymers with macro-ultra macro porosity;

- mesoporous geopolymers with unidirectional macro-ultra macro lamellar porosity;

- mesoporous spheres and granules with lamellar, globular porosity and / or metallic functional oxide.

In the context of international collaborations and national projects such as PNRR, PRIN, PON and POR-FESR, as well as industrial research contracts, hierarchically organized porosities have been developed and prototypes of pre-industrial dimensions have been produced and/or the composition of the material has been developed through the mix-design.

The PRIN GEA projects coordinated by CNR-ISSMC, POR FESR SMARTH2O and PNRR ECOSISTER (SPOKE 3 and 5) deal with the adsorption/separation/recycling of CO2 and pollutants from wastewater.

Gas separation / CO2 adsorption: due to their porosity distributed over different length scales and a zeolite-like molecular structure, geopolymers have good selective adsorption capacity of CO2. Both in the form of granules and as monoliths they can be used in post-combustion CO2 capture equipment with efficiencies slightly below those of other materials (eg active carbons) but with better mechanical strength and shaping properties.

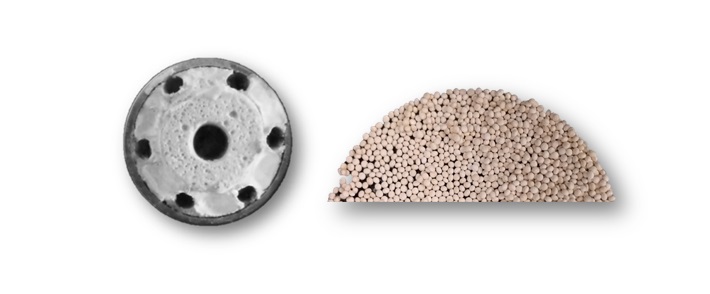

Purification of wastewater from pollutants: wastewater contains various pollutants such as heavy metals, ammonium and phosphate (which promote eutrophication) and dyes mixed with various contaminants are one of the major causes of environmental pollution. Geopolymers, thanks to their zeolitic structure, can be effectively used in ion exchange absorption, which is one of the most efficient methods for water purification. In particular, millimeter-sized geopolymer spheres are the simplest to use in an industrial context.

CLC – Chemical Looping Combustion is a technique that allows the inherent separation of CO2 produced from fossil fuel, from combustion air nitrogen through the chemical transport of oxygen. Similarly, the Chemical loop can be used for other processes such as separating O2 from the air or generating pure hydrogen. Metallic oxide functionalized geopolymers can be used in the form of granular or macro-porous monoliths in high temperature cycles for CLC combustion of methane and syngas.

In the framework of the POR-FESR TERMOREF project (2016-2018), innovative “green” composite catalysts for the TAR reforming have been developed, consisting of active oxides dispersed in a geopolymeric matrix. The same materials were also positively tested as oxygen carriers in chemical looping combustion processes.

Within PON01_00375 “PANDION a Loop Heat Pipe evaporator (LHP) has been produced containing two differentiated porous concentric geopolymeric wicks. A heat pipe is a device that can exchange large quantities of heat with a very small temperature difference between the hot and cold interface, by evaporating and condensing a working fluid. An LHP consists of an evaporator (capillary pump), a compensation chamber, a capacitor and lines of steam and liquid. The final device was tested by SAB srl with TRL 5.

Tools and Processes

Direct and indirect foaming techniques such as blowing agents or ice templating must be suitably adapted to geopolymeric materials by setting process parameters so as to avoid interference with the geopolymerization. The spherification methods (injection and consolidation in PEG, liquid nitrogen and ionotropic gelation) allow the production of millimetric spheres (2-3 mm depending on the process) at different industrial levels, with different porosity, suitable for water remediation processes. The Cold Sintering Process (CSP) is used to produce geopolymer membranes from waste geopolymer and zeolite through the application of pressure and temperature, in the presence of minimal quantities of activator.

Main collaborations

- SPCTS Università di Limoges

- Dipartimento di Chimica industriale “Toso Montanari” Università di Bologna

- Dipartimento di Ingegneria Civile, Chimica, ambientale e dei materiali (DICAM) Università di Bologna

Projects

Publications and patents

- A Natali Murri, E Papa, V Medri, F Miccio, E Landi, Fe/Mn oxide-based foams via geopolymerization process as novel catalysts for tar removal in biomass gasification, Journal of the European Ceramic Society 44, 2024, 2560-2570.

- V Medri, E Papa, E Landi, C Maggetti, D Pinelli, D Frascari, Ammonium removal and recovery from municipal wastewater by ion exchange using a metakaolin K-based geopolymer, Water Research 225 (2022) 119203.

- V Medri, E Papa, M Mor, A Vaccari, A Natali Murri, L Piotte, C Melandri, E. Landi, Mechanical strength and cationic dye adsorption ability of metakaolin-based geopolymer spheres, Applied Clay Science 193 (2020) 105678.

- A. Natali Murri, F. Miccio, V. Medri, E. Landi, Geopolymer-composites with thermomechanical stability as oxygen carriers for fluidized bed chemical looping combustion with oxygen uncoupling, Chemical Engineering Journal 397 (2020) 124756.

- Minelli M., Papa E., Medri V., Miccio F., Benito P., Doghieri F., Landi E., Characterization of novel geopolymer – zeolite composites as solid adsorbents for CO2 capture, Chemical Engineering Journal 341 (2018) 505-515.