This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. More information in our Privacy Policy

New energetic nanomaterials synthesis

Synthesis of nanoparticles for energetic applications

Principal investigators: Angela Gondolini, Alessandra Sanson

Involved personnel: Elisa Mercadelli

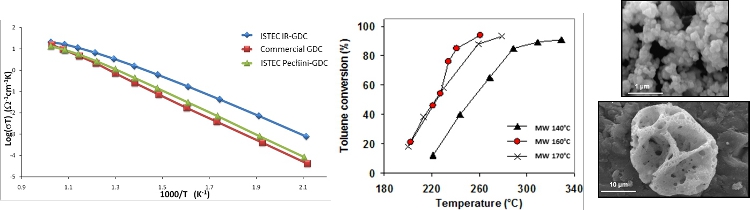

Besides the process technologies used, the successful production of highly efficient ceramics is strictly related to the chemical-physical characteristics of the starting powders. For this objective, CNR-ISTEC has implemented a conventional synthesis method applying innovative heating systems for the production of ceria-based powders or perovskite-related systems with high chemical-physical reactivity and high purity and morphological control. These systems have been exploited for catalytic applications such as toluene synthesis and as high-efficient electrolytic powders for SOFC/SOEC applications as well as for solar conversion processes.

Equipment and processes

Micro-wave furnace

Main partners

- Istituto di Chimica della Materia Condensata e Tecnologie per l’Energia (CNR-ICMATE)

- Istituto per la Sintesi Organica e la Fotoreattività (CNR-ISOF)

- Istituto di Chimica dei Composti OrganoMetallici (CNR-ICCOM)

Publications

- Gondolini, E. Mercadelli, A. Sanson, S. Albonetti, L. Doubova, S. Boldrini, “Effect of the microwave heating on the properties of gadolinium-doped cerium oxide prepared by polyol method” Journal of the European Ceramic Society 33 (2013) 67-77.

- Gondolini, E. Mercadelli, A. Sanson, S. Albonetti, L. Doubova, S. Boldrini “Microwave-assisted synthesis of gadolinia-doped ceria powders for solid oxide fuel cells”, Ceramics International 37 (2011) 1423-1426.

- E. Mercadelli, G. Ghetti, A. Sanson, R. Bonelli, S. Albonetti “Synthesis of CeO2 nano-aggregates of complex morphology” Ceramics International 39 (2013) 629–634