Solid oxide fuel and Electrolysis cells (SOFC-SOEC)

Principal investigator: Alessandra Sanson

Involved personnel: Elisa Mercadelli, Angela Gondolini

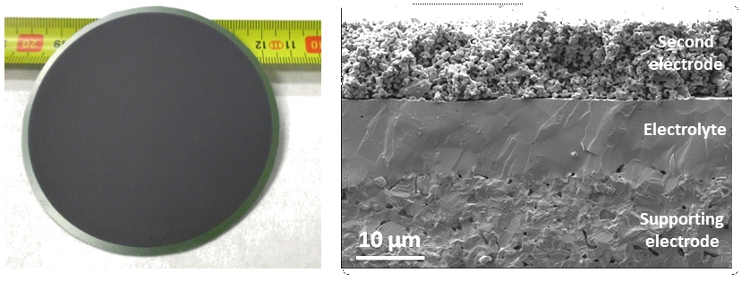

SOFC and SOEC are produced at ISSMC starting from powders obtained by conventional solid state synthesis or chemical routes (precipitation, sol-gel, etc.). The powders are synthesized with characteristics suitable for the subsequent shaping processes. The cell fabrication consists in depositing the cell elements onto a supporting-element produced by tape casting. Three generation of cells (electrolyte, electrode and metal supported) were produced using the following materials:

- Oxygen electrodes: La0.6Sr0.4Fe0.8Co0.2O3 (LSCF), La0.8Sr0.2MnO3 (LSM) LSCF-GDC, LSM-YSZ, LSM-GDC;

- Fuel electrodes: NiO/(Zr,Y)O2, NiO/Ce0.8Gd0.2O2, NiO/ Ba(Ce,Y,Zr)O3, (Sr,La,Ti)O3, (La,Sr,Cr,Mn)O3;

- Electrolytes:(Zr,Y)O2, (Zr,Sc)O2, Ce0.8Gd0.2O2, Ba(Ce,Y)O3, (La,Sr,Ga,Mg)O3;

- Metal substrates: Ni, Stainless steel, NiCrAl foam.

Products with dimensions up to 10 x10 cm2 were obtained after the thermal treatment needed to reach suitable densification or porosity level for the electrolyte or the electrodes respectively.

Main partners

Projects

Publications

- Gondolini, E. Mercadelli, G. Constantin, L. Dessemond, V. Yurkiv, R. Costa, A. Sanson “On the manufacturing of low temperature activated Sr0.9La0.1TiO3-δ-Ce1-xGdxO2-δ anodes for solid oxide fuel cell” Journal of the European Ceramic Society, http://dx.doi.org/10.1016/j.jeurceramsoc.2017.07.035.

- Gondolini, E. Mercadelli, A. Sanson “Single Step Process for Cathode Supported half-cell”, 10th European SOFC Forum, Lucerna, 26-29 June 2012.

- I. Luisetto, S. Licoccia, A. D’Epifanio, A. Sanson d, E. Mercadelli, E. Di Bartolomeo “Electrochemical performance of spin coated dense BaZr0.80Y0.16Zn0.04O3-d membranes” Journal of Power Sources, 220 (2012) 280-285.