SUSPENCE

SUper Strong ceramics for Protection in harsh ENvironments and defenCE

Principal Investigator: Laura Silvestroni

Involved personnel: Diletta Sciti, Nicola Gilli, Simone Failla, Alex Sangiorgi, Cesare Melandri, Claudio Capiani

Starting date: 15/09/2020

Duration: 36 months

Total funding: 300.000€

Action: NATO Emerging Security Challenges Division, SPS Programme

CNR-ISTEC Role: Project Coordinator

Partnership: Institute of Technical Sciences of the Serbian Academy of Sciences and Arts (ITS-SASA) – Serbia, Missouri Science and Technology University (MS&T) – U.S, Industrie Bitossi S.p.A. (Italy), Italian Aerospace Research Centre – CIRA (Italy)

Website: www.suspence-natosps.it

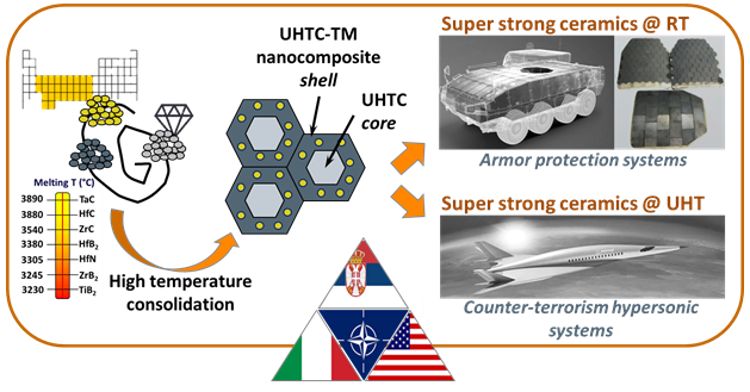

SUSPENCE proposes innovative technological solutions to address the SPS Key Priorities that regard protection of personnel, critical assets and infrastructures by development of nano-structured super strong ceramics able to operate in harsh environments. Harsh here defines two major fields: i) ballistic protection, where high strength, stiffness, and hardness with low weight is required to dissipate high energy impacts and resist penetration of the projectile into the body armor, and ii) hypersonic systems, which require materials able to survive to important heat fluxes as well as aerodynamic and mechanical loads.

Current available materials suffer of a series of technological limitations, like not favourable performance and production cost to weight ratios or inability to perform under hot ablative fluxes. Ultra-high temperature ceramics (UHTCs) are possible candidates that, upon suitable composition and microstructure tailoring, can offer a solution to both areas.

SUSPENCE will develop novel materials with reduced costs and improved mass efficiency of ballistic protection materials and also extend the performance and lifetime of hypersonic systems.

This will be accomplished by merging titanium diboride (TiB2) with a secondary very hard phase and a transition metal (TM) compound to exploit the multiple benefits of the single phases, Fig. 1. Key to the achievement of high strengths from room temperature and up to at least 2000°C, is the development of a particular morphology, called core-shell. This comprises a core with the nominally pure diboride grain seed, i.e. TiB2, and a solid solution shell that contains variable amounts of a second TM cation, i.e. (Ti,TM)B2. By adequate sintering and post-densification thermal treatments, we will promote development of the shell into a hierarchical UHTC-TM nano-composite consisting of homogeneously distributed nano-sized metallic inclusions embedded in micron-sized ceramic grains that will offer benefits by increase of local fracture toughness and strength, significant plastic deformation and ability to support high loads in the ultra-high temperature regime and enhanced oxidation behaviour.

The developed compositions will be then tested in relevant conditions.

Publications & Patents

- L. Silvestroni, S. Failla, N. Gilli, C. Melandri, U. Savacı, S. Turan, D. Sciti, “Disclosing small scale length properties in core-shell structured B4C-TiB2 composites”, Materials & Design 197 (2021) 109204.

- L. Silvestroni, N. Gilli, A. Migliori, D. Sciti, J. Watts, G.E. Hilmas, W.G. Fahrenholtz, “A simple route to fabricate strong boride hierarchical composites for use at ultra-high temperature”, Composites B 183 (2020) 107618.

- R.J. Grohsmeyer, L. Silvestroni, G.E. Hilmas, F. Monteverde, W.G. Fahrenholtz, A. D’Angió, D. Sciti, “ZrB2-MoSi2 ceramics: a comprehensive overview of microstructure and properties relationships. Part II: Mechanical properties”, Journal of the European Ceramic Society, 39 [6] (2019) 1948-1954.

- L. Silvestroni, S. Failla, V. Vinokurov, I. Neshpor, O. Grigoriev, “Core-shell structure: an effective feature for strengthening ZrB2 ceramics”, Scripta Materialia 160 (2019) 1-4.

- L. Silvestroni, K. Stricker, D. Sciti, H.-J. Kleebe, “Understanding the oxidation behavior of a ZrB2–MoSi2 composite at ultra-high temperatures”, Acta Materialia, 151 [1] (2018) 216-228.

- L. Silvestroni, S. Failla, I. Neshpor, O. Grigoriev, “Method to improve the oxidation resistance of ZrB2-based ceramics for reusable space systems”, Journal of the European Ceramic Society, 38 [6] (2018)2467-2476

- L. Silvestroni, H-J. Kleebe, W.G. Fahrenholtz, J. Watts “Super-strong materials for temperatures exceeding 2000°C”, Sci. Rep. 7, 40730; doi: 10.1038/srep40730 (2017). 4.259

- L. Silvestroni, H-J. Kleebe, “Critical oxidation behavior of Ta-containing ZrB2 composites in the 1500-1650°C temperature range”, Journal of the European Ceramic Society, 37 (2017) 1899–1908. 3.794

- L. Silvestroni, D. Sciti, F. Monteverde, K. Stricker, H-J. Kleebe, “Microstructure evolution of a W-doped ZrB2 ceramic upon high-temperature oxidation”, Journal of the American Society, 100 [4] (2017) 1760-1772.

- F. Monteverde, L. Silvestroni, “Combined effects of WC and SiC on densification and thermo-mechanical stability of ZrB2 ceramics”, Materials & Design 109 (2016) 396–407. 4.364

- L. Silvestroni, D. Sciti, “TEM analysis, mechanical characterization and oxidation resistance of a highly refractory ZrB2-composite”, Journal of Alloys and Compounds B, 602, 346-355 (2014).

- L. Silvestroni, D. Sciti, “Transmission electron microscopy on Hf- and Ta- carbides sintered with TaSi2”, Journal of the European Ceramic Society 31 (2011) 3033–3043

- L. Silvestroni, D. Sciti, “Densification of ZrB2–TaSi2 and HfB2–TaSi2 Ultra-High-Temperature Ceramic Composites”, Journal of the American Ceramic Society, 94 [6], 1920-1930 (2011)

- L. Silvestroni, H-J. Kleebe, S. Lauterbach, M. Müller, D. Sciti, “Transmission Electron Microscopy on Zr- and Hf-borides with MoSi2 addition: Densification Mechanisms”, Journal of Materials Research 25 [5] 828-834 (2010).