Questo sito Web utilizza i cookie in modo da poterti offrire la migliore esperienza utente possibile. Le informazioni sui cookie sono memorizzate nel tuo browser e svolgono funzioni come riconoscerti quando torni sul nostro sito Web e aiutare il nostro team a capire quali sezioni del sito Web ritieni più interessanti e utili. Per maggiori informazioni consulta la nostra Privacy Policy.

MI-WINE

Mild innovative treatment for wine stabilization

Principal investigator: Anna Luisa Costa

Involved personnel: Marina Serantoni, Magda Blosi, Carlo Baldisserri, Andrea Brigliadori, Antonio Crimaldi, Lara Faccani, Davide Gardini, Simona Ortelli, Felice Carlo Simeone, Ilaria Zanoni

Starting date: 01/11/2020

Duration: 36 months

Total funding: 239 000 €

Proposal ID: 87

Call: SUSFOOD2 and CORE Organic Cofunds Joint Call

Topic: Towards sustainable and organic food systems

Coordinator: Giuseppina Paola Parpinello (DISTAL-Università di Bologna, Italy)

Consortium: 4 partners

MI-WINE is aimed at the creation of an innovative adsorbent material (NAMS) for protein and oxidative stabilization of wines and vegetable drinks, and the use of this material in a continuous flow treatment system, validated on a laboratory scale. This approach lays the foundations for the development of a food technology characterized by high sustainability; the continuous treatment of variable volumes of liquid intends to satisfy the requirements of a typical supply chain treatment, to facilitate the future transfer on an industrial scale.

The parameters on which this project concern:

1) Waste volume produced following stabilization treatments of wines and vegetable drinks.

The traditional treatments adopted for the industrial stabilization of wines and beverages are static; the materials used cannot be regenerated for subsequent treatments, they must be removed, and this generates high volumes of waste destined for disposal. The proposed material can be regenerated for several cycles to be defined in the design phase, with a quantitative reduction in the volumes of waste generated.

2) Timing related to the treatments applied in the wine and vegetable drinks supply chain. Traditional treatments require long times, in the order of hours-days, to obtain satisfactory stabilization parameters meeting the requirements for placing wines / beverages on the market. To date, there is no single treatment that can preserve wine and beverages from phenomena of protein and oxidative instability simultaneously, but separate protocols must be applied. As for protein stabilization, traditional materials must be removed from the liquid at the end of the treatment, and this involves further filtration and decanting operations. The proposed treatment involves the passage of the product to be treated through the flow system, which involves packing and immobilization of the material in an inert column; this reproduces the modalities of a typical industrial treatment in a continuous flow regime. The treatment cycles, which can be repeated, involve shorter times than the static treatments; there is no need for decanting and filtration; protein and oxidative stabilization are carried out simultaneously in a single treatment.

3) Balance of product volumes (losses / recovery).

Transfer and filtration operations envisaged by traditional stabilization protocols involve inevitable losses of product volumes. The implementation of a flow treatment minimizes these losses; their percentage reduction on a laboratory scale is one of the quantitative parameters to be defined within the project, to facilitate subsequent scaling-ups within the company.

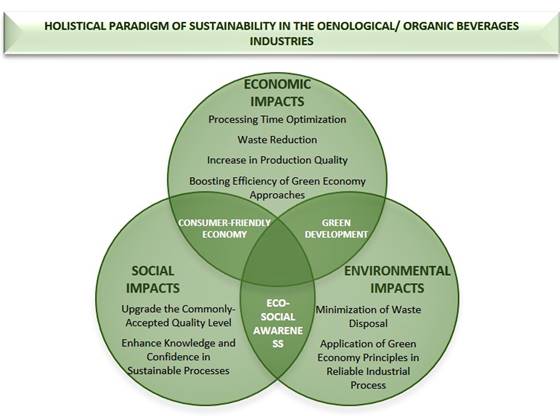

4) Environmental, economic, and social impact indicators.

Perhaps the most important quantitative parameter for the purposes of technology transfer, the assessment of the environmental impact (reduction of waste volumes connected to the production process) and economic (reduction of product disposal costs), with an inevitable social impact (increase consumer confidence and expectation).

Partners:

Department of Agricultural and Food Sciences DISTAL UNIBO – Alma Mater Studiorum – Università di Bologna, Italy

Institute of Science and Technology of Ceramic Materials ISTEC – CNR Consiglio Nazionale delle Ricerche, Italy

Institute for Viticulture and Oenology, Dienstleistungszentrum Ländlicher Raum, DLR Rheinpfalz, Neustadt, Germany

Wrocław University of Environmental and Life Sciences – Department of Chemistry Wrocław, Poland